Achieving this requires a strategic approach, starting with finding the right robotic welding specialist systems integrator. Their expertise will shape the success of your automation journey, ensuring alignment with your goals, your daily tasks, and future visions.

Defining a system that's not only precise but also scalable is key. It's about anticipating tomorrow's challenges today and investing wisely. With technology advancing at lightning speed, and Australian government incentives awaiting those ready to embrace automation, there’s no time to waste. Use this opportunity to future-proof your business or risk being left further behind.

5 Benefits of Robotic Welding

- Consistent Productivity

- Reduce Labour Costs

- Increased Quality and Efficiency

- Safer Operations

- Conserve Raw Materials

Step 1. Find a suitable integrator.

Selecting a recognised robotic welding integrator for your application is paramount to the success of your project. Begin by identifying integrators with proven local tech support and experience and expertise in your specific sector, before requesting a complimentary audit to assess their suitability for your needs.

An integrator's capabilities can be evaluated by examining similar systems they've implemented. Their ability to provide local servicing and parts is often overlooked but is crucial for maintaining your system, whilst also proactively enhancing future performance.

Communication is key - The integrator must be aware of your expectations, productivity targets, accuracy standards, and future visions. Estimating your available space, resources, budget, and automation skills gap, will ensure clarity throughout the process, and avoid limitations of your new production system.

By carefully selecting the right robotic welding integrator that suits your needs, you will set the foundation for a successful and enduring partnership in automation implementation.

Step 2. Define the system.

Finding a targeted welding system that is both precise and scalable for your future production volumes is paramount for long-term success in manufacturing. Scalability anticipates and accommodates growth without the need for frequent system upgrades or replacements.

By investing in a scalable automation solution, manufacturers can optimise productivity, maintain competitiveness, and future-proof their operations against evolving market demands.

Robotic welding systems are considered a productive solution capable of scaling up your capabilities, which is one of the most targeted grant funding expectations. Your integrator should have access to specialists who can source applicable grants, before composing and submitting your application.

Step 3. Implement a timeline.

The implementation timeframe of a new robotic welding system holds significant importance in minimising disruptions to the production process. Constructing a well-planned timeline is essential to ensure the efficient setup of the new system while considering various factors such as available resources, cash flow constraints, ongoing projects, and production backlogs. It's crucial to anticipate potential challenges and allocate sufficient time and resources accordingly to mitigate any impact on operations.

Additionally, budget and timing allowances must be allocated for the fabrication of future jigs and accessories, ensuring seamless integration with the new system. Upon completion of delivery, installation, and testing phases, the training component becomes paramount. Comprehensive training programs must be implemented to equip all staff with the necessary skills to operate the system proficiently.

By carefully orchestrating each stage of the implementation process within a structured timeline, businesses can minimise impacts, and seamlessly transition to the new integration system without any surprises.

Integrating robotic automation into your manufacturing business requires experienced planning and execution across three key steps. Finding a suitable integrator, defining the system parameters, and managing the implementation timeline are vital for success.

RA are integration experts and have provided over 3,500 installations across ANZ over the last 36 years, making them well-equipped to guide businesses through this process. Their high-level tech support and preventative maintenance packages are available to limit production down-time and maximise productivity.

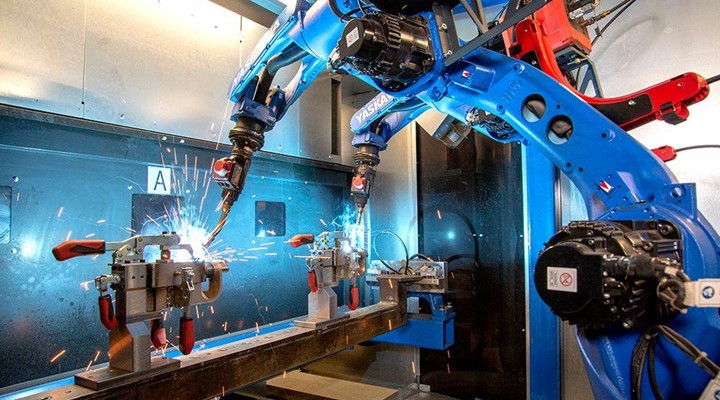

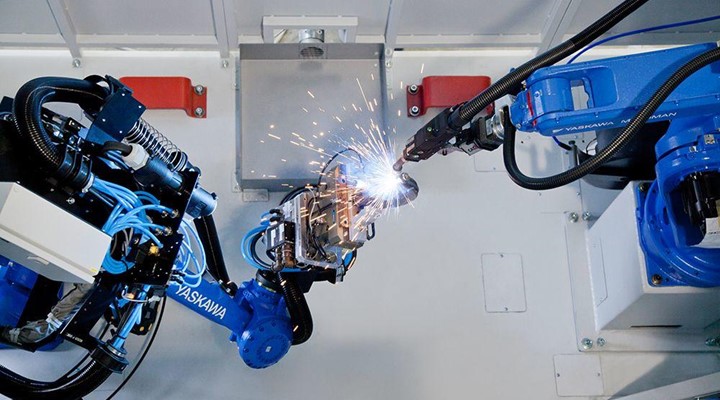

RA’s welding division utilises robotic experts, welding engineers and a solutions team with exclusive access to one of the worlds largest industrial robotic welding libraries from Yaskawa Motoman. They can provide complete packages fully tailored to your requirements, using system components all from a single source for seamless compatibility during the integration process.

By partnering with RA, businesses can confidently navigate the complexities of automation, optimising productivity, and future-proofing operations.

(1)-205x205.jpg)