Airborne contamination is the most difficult form of contamination to protect against. The ingress of contaminated airborne particles puts everything in the warehouse at risk, and this means nothing but a complete seal is adequate.

Airborne contaminants can be segmented into aerosols (fine solid or liquid particles in gas) and bio aerosols (fungi, bacteria and pollen).

A third category of airborne contamination threats should also be considered – that of flying pests like flies and birds. Flies and birds are carriers of disease and contaminants which may stay behind long after the actual presence of pests has gone.

Whilst contaminants are capable of entering the materials handling cycle through ventilation, gaps in walls and windows, the major ingress within a facility is through doorways. Doors present the largest transfer area and are the most crucial feature to consider in your airborne contamination prevention efforts.

Remax highlights some major things to consider when attempting to use your doors to reduce airborne contamination in your facility.

|

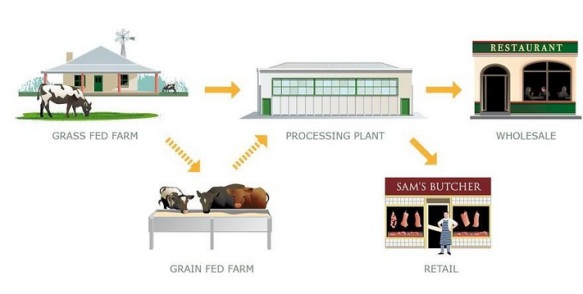

| From the farm to the local market: meat has a long way to travel. |

Quick operation

It's a simple equation: the less time doors are open in your facility, the less opportunity there is for contaminants to enter.

The ways in which you can reduce open time are numerous and choosing the right course of action involves weighing all factors. Doors with heavy traffic suffer from maintenance issues following frequent usage, as well as damage caused by crashes.

It is important that you choose a door that is resilient and reliable for this purpose but quick enough to reduce open times. A door made of substandard parts will break down more frequently, creating delays and potentially being open permanently until fixed.

Look at the warranty. If the door's manufacturer or supplier has no long-term guarantees or support, you should be asking: "Why not?"

Rapid doors are essential in blocking the aerosols that follow in the wake of a forklift when it crosses through the doorway. The ultimate solution is a fast, good quality and long lasting door.

Self-repairing features

While the speed and reliability of the mechanical elements of the door are important, it is also crucial to consider the seal of the door.

The tighter the seal, the less opportunity there is for ingress of contaminants. Impact is one of the major causes of broken seals and that is why investing in rapid doors with a crash-out or self-repairing feature is really important.

High-speed doors should be fast enough to avoid major collisions but having a crash-out feature. High-speed doors like the Movidor from Remax Products allow the door to be knocked out from its guide without damaging the seal; the door will then realign automatically.

Lower cost rapid doors with no crash-out feature will normally require a call out to realign the door back into its tracks and therefore carry regular unforseen additional costs on a monthly basis.

You are very likely going to save on maintenance costs in the long run by purchasing a slightly more advanced door containing self-repairing features, and therefore requiring less call-out fees throughout the life of the door.

This feature is part of what keeps downtime to a minimum, but of equal importance is the way it keeps the seal unimpaired throughout the door's lifespan. It is important to consider other contamination possibilities involved with the door.

Shedding contaminants

Another major feature is the ability of the door to shed dirt, dust and contaminants both in its everyday function and during wash down.

Roller doors such as the ones described above, should be easily washable and made of an appropriate fabric that is fully extended when the door is closed, preventing any microbial and debris build-up around the drums.

All exposed mechanical metal parts should also be constructed using stainless steel to reduce rust and wear and tear.

Remax has a free guide offering further tips on contamination prevention in food manufacturing.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)