Modern hardware can't get by without software. Often there is one fundamental decision to make: whether to use individual, complex, in-depth programming or simply drag and drop with ready-made software blocks.

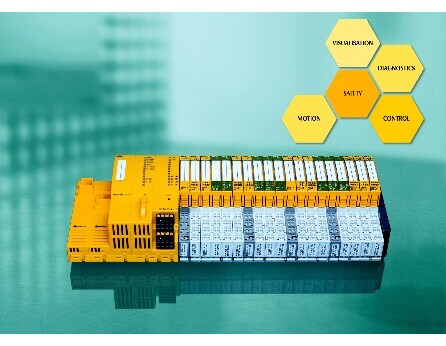

The new automation system PSS4000 combines these two seemingly conflicting methods in one tool. The software platform PAS4000 accommodates a wide range of programming abilities: from first-timers to professionals.

The market reveals a trend towards universal, complete solutions, in which programmable safety technology is linked ever closer with standard control technology. And this is where the new automation system comes in: with PSS4000, Pilz is the first to combine the safety and standard sections, making safety technology easier to program in the process.

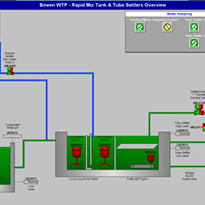

The automation system can be used to build control structures that are very complex, and yet are still easy for the user to operate. The PSS4000 enables you to reap the benefits of a decentralised control structure without having to face the higher complexity that this would normally involve. Thanks to the software platform PAS4000, users can not only retain an overview of a decentralised automation system with distributed control functions, but also have a tool to hand which enables them to create applications simply and flexibly.

Ready-made software blocks or proprietary programming

The graphics editor PASmulti enables the necessary functions to be configured with ease. The editor has been developed from the proven, user-friendly configuration tool for the PNOZmulti safety system, which has been extended to incorporate standard automation technology.

The software platform provides the IEC 61131-3 languages for proprietary programming. The full, standardised instruction set is available for standard control functions and, for the first time, safety functions too. The programming languages start with IL (Instruction List), followed by ST (Structured Text).

This way Pilz has managed to merge a variety of levels within the software platform: a pure programming level for experts and a superimposed level on which the complexity is virtually hidden, enabling functions to be configured with ease.

Both levels merge to form a powerful, yet simple tool. On less complex machines with straightforward safety functions, the whole safety solution can be created simply and quickly using the software blocks supplied by Pilz. On larger applications with more demanding safety requirements, the user is able to structure his application very clearly through configuration with PASmulti; individual sections can then be programmed in accordance with IEC 61131-3. Parameters for these self-written safety functions can then be set and linked very easily.

So programming and configuration are merged and blocks are "composed", so to speak. Ready-made program sections can be combined in this way, to cover complete plant functions.

Another special feature is the fact that programming is independent of the hardware. Each function can be used with total flexibility, whether it's from the Pilz block library or from the library that the customer has created himself. The benefit lies in the fact that the system is not dependent on a specific CPU or on specific inputs and outputs. When using the block, the software platform PAS4000 merely checks that the combination of the block, executing CPU and assigned I/Os provides the required performance level (PL). The resulting flexibility is particularly beneficial to the user when subsequent changes are to be implemented.

Clarity even on components with a wide range of functions

The selection of ready-made components or software blocks from libraries is itself nothing new. However, on PSS4000 these components are given properties, which allow the parameters for the required functions to be easily set via drag and drop. The primary benefit in this case is the ability to standardise functions: previously the user had to ask himself how many functions he could bundle into a block without adversely affecting clarity.

In practice the result was either a vast number of blocks, or too few blocks with a vast number of parameters. Now the user can "write" his optimum component and create a user level for its application, through which he can select the various functions. As a result, only the selected function is visible as a parameter; the component itself hides any complexity and remains easy for the user to manage.

Clear division of tasks and mechatronic operation

The additional advantage for companies in merging the IEC 61131-3 programming languages and a graphics editor within one software platform is that, in terms of human resources, tasks can be clearly divided into programming and commissioning. In the best case scenario, during commissioning components will only have to be adjusted, which can easily be achieved through the software blocks. Pilz also supports this procedure by providing software libraries containing the most common basic functions, elements and modules. So human resource costs during commissioning are significantly reduced.

Mechatronic operation is based on modularity. Hardware and programming tools must embrace and support this concept. PSS4000 was developed as a modular, decentralised automation system. By transferring control functions to machine modules and enabling both safety and control functions at hardware level to be handled independently in one unit, a complex machine can be assembled out of the modules. These modules can be reproduced in the software.

Modularisation is a key aspect of PAS4000: Elements are created from the basic functions; the elements in turn create modules and the modules create plant and machinery. All this is achieved simply through hierarchical nesting of the software blocks. Basic functions, elements and modules form the backbone of the software development and are ideal to re-use as software components thanks to encapsulation and object orientation.

Even the simple handling of PAS4000 embraces the mechatronic approach. If the mechatronic principle is applied strictly it may mean, for example, that not all faculties are present during a machine's commissioning phase - i.e. mechanical and electrical design engineer, software developer. Instead, these functions are all combined in the form of qualified mechatronic engineers, who should be able to make any necessary changes to the control program themselves, without having to refer back to designated experts.

The strict alignment of the automation system PSS4000 to a modular approach with distributed control functions and SafetyNET p as the communication system allows the user to respond very flexibly to the requirements of a specific automation solution. The fact that PAS4000 establishes the communication links between the distributed elements automatically in the background is just one of many pieces in the puzzle, which collectively help to create a time-saving solution.