CBC is the Oceania master distributor for Canadian company One Eye Industries (OEI), manufacturer of environmentally friendly filtration systems with rare earth magnetic technology and reusable long life filters.

OEI provides magnetic filtration solutions in the oil and gas, marine, manufacturing, mining and associated industries to effectively filter and remove ferrous and non-ferrous contamination in lube oil, hydraulic fluid, fuel, coolant, gear oil, glycol, process/effluent water and amines.

Generating ferrous contaminants in most hydraulic and lube systems due to wear is a fact of life. Knowing the amount and type of wear particles in the fluid system is critical to avoiding unscheduled downtime.

Standard filter elements only capture particulate contamination within their media matrix according to their micron rating. Identification of the contamination typically requires off-site laboratory analysis.

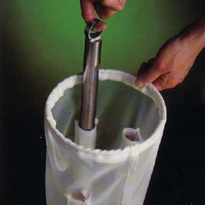

OEI’s built-in magnetic filter cores capture ferrous contaminants in fluid systems, down to <1µm, before they reach the actual filter, providing an excellent diagnostic tool for contamination monitoring and proactive maintenance.

Using static adhesion, the cores also retain some of the non-ferrous contaminants. By simply removing the magnetic core and examining the retained contamination under a microscope, reliability and maintenance engineers have a valuable tool for identifying potential wear-related issues before they become a real problem.

Studies show that ferrous particles smaller than 10 microns generate 3 to 5 times more wear than larger particles as these contaminants are carried into high pressure contact areas causing damage to softer metals, seals, bearings and gaskets.

OEI’s patented magnetic technology traps these sub-micron ferrous and some nonferrous contaminants, especially in high flow and/or high viscosity fluids, reducing wear and increasing equipment life.

The benefits of monitoring and removing submicron contaminants from gas and fluids equipment

- Dramatic reduction of the damaging wear cycle, extending the life of fluids and equipment

- Longer periods of in-service operation due to the reduced oxidation rate of oils

- Reduced oil consumption

- Reduced fuel consumption

- Longer equipment life

- Extended service intervals

- Enhanced accuracy of machine condition analysis

- Longer conventional filter life

- Fast and simple on-site identification of contaminants

- Filtration solutions for applications previously impossible using conventional filters

- Reduced impact on the environment through reduced oil consumption, reusable filters and reduced component replacement

Magnetic Filter Pads

Designed to complement existing disposable filters for lube oil, fuel, hydraulics and coolant applications.

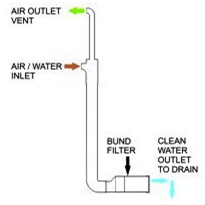

Magnetic Filter Rods, Y Strainers and Scrubbers

Designed for installation prior to traditional filters in reservoirs and applications previously unsuitable for filtration.

Add-Vantage 9000 Series

Designed to replace disposable filters, combining cleanable stainless steel elements and magnetic filter technology in one filter with 40% greater flow capacity than traditional paper elements.

Filter Plugs

A simple and effective way to capture ferrous contaminants is to replace filler and drain plugs with magnetic plugs.

Cone and Basket Strainers

Magnetic rods in OEI’s cone and basket strainers capture small particles that would otherwise pass through the basket mesh, minimising erosion in large pipelines and damage to instruments. The strainers may be removed after plant start up while leaving the magnetic rods to continue to offer protection.