The CAD$460,000 order from a global EPCM consultancy is for the installation of a system of 272 voltage and temperature monitors.

"This order is significant because it is the first time it will be used in a nickel electrowinning application, the order comes from a major EPCM provider and the end user is one of the world's leading mining and mineral processing companies," Tony Mathison, CellView developer and Mipac Director, said.

The CellView monitoring system realises the full potential of a refining or electrowinning operation by detecting changes in a plant and acting as a critical first indicator of process problems including inter-electrode shorts, passivation, poor contacts, reagent control, electrolyte temperature, electrolyte flow and electrolyte contamination issues.

"CellView increases production, increases fault detection capabilities in cells, reduces maintenance requirements, minimises point cost and keeps things simple," Mathison said.

"It also boosts operator safety and at the same time makes it possible to increase the quality and quantity of output using the same level of input."

Tony expects demand for CellView to grow significantly in the next few years.

"It has great potential globally, as well as in Australia.

"It is currently performing in the Glencore-owned Kazzinc copper refinery in Kazakhstan where from the first day of operations it has helped produce high-grade copper, improving levels of operational excellence.

"CellView's" continuous real-time monitoring of cell performance is the first step towards improving tankhouse management; and it is a fine example of how Australia's leading process control engineers are contributing to the success of world-class mining operations."

CellView: the nuts and bolts

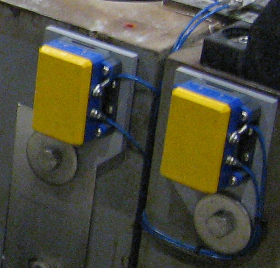

CellView, a wireless cell monitor, is mounted on each electrowinning/electro-refining cell. Individual monitors are enclosed in industrial-quality housing and contain voltage and (optional) temperature measurement circuitry, a radio transmitter, an RFID tag (for set up and asset management) and a non-rechargeable, long-life battery (up to 10 years, depending on cycles).

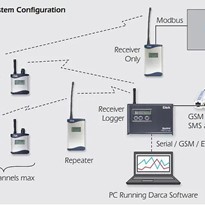

The monitor communicates via a robust, state-of-the-art mesh network optimised to work in harsh and noisy environments, and operates effectively in aggressive chemical locations.

Information is fed to a central operator interface which can be integrated into an existing system or can stand alone. An OPC interface is also available.

Recognising Mipac's leadership in engineering and technological excellence, CellView won a PACE Zenith Award in 2009 in the metal products category.

Visit MIPAC's CellView web page for more information about how it helps plants achieve operational excellence.