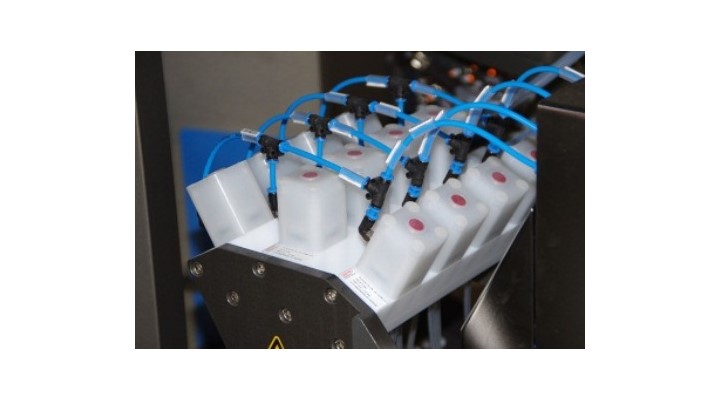

The task was solved by using a multi-port valve block from the iComLine® series, which is made of ultra pure PVDF and features innovative seat diaphragm technology with PTFE. This combination allows very heavy-duty switching cycles and temperature resistance up to 150 °C. Features which were not possible with the pinch valves used previously.

Multi-port valve blocks combine multiple valve seats in one unit. This means that plants can now be built much more compactly because the pipe connections, fittings and even various sensor components can be integrated together.

Through customiSed calculations and configuration of the regulating cones, it is possible to implement open/close functions along with very specific control characteristics. In this case, three millilitres of ultra pure water are output precisely within just 60 milliseconds.

Thanks to a wealth of experience acquired over 20 years in the manufacture of stainless steel multi-port valve blocks and in handling critical media in the semiconductor industry, GEMÜ has now been able to successfully transfer this expertise to the field of high-performance thermoplastics.

With its modular system, GEMÜ can provide individually adapted customer solutions to meet specific requirements and supplies everything from a single source.