Tension wood, which forms naturally in hardwood trees in response to bending stress, is known to possess unique features that render it desirable as a bioenergy feedstock.

Although individual elements of tension wood have been studied previously, the Department of Energy's BioEnergy Science Center (BESC) team is the first to use a comprehensive suite of techniques to systematically characterise tension wood and link the wood's properties to sugar release.

Plant sugars, known as cellulose, are fermented into alcohol for use as biofuel.

"There has been no integrated study of tension stress response that relates the molecular and biochemical properties of the wood to the amount of sugar that is released," Oak Ridge National Laboratory's Udaya Kalluri, a co-author on the study, said.

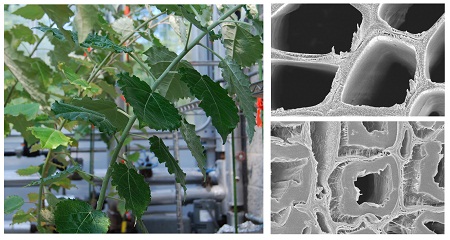

The work, published in Energy & Environmental Science, describes tension wood properties including an increased number of woody cells, thicker cell walls, more crystalline forms of cellulose and lower lignin levels, all of which are desired in an biofuel crop.

"Tension wood in poplar trees has a special type of cell wall that is of interest because it is composed of more than 90 per cent cellulose, whereas wood is normally composed of 40 to 55 per cent cellulose," Kalluri said.

"If you increase the cellulose in your feedstock material, then you can potentially extract more sugars as the quality of the wood has changed. Our study confirms this phenomenon."

The study's cohesive approach also provides a new perspective on the natural plant barriers that prevent the release of sugars necessary for biofuel production, a trait scientists term as recalcitrance.

"Recalcitrance of plants is ultimately a reflection of a series of integrated plant cell walls, components, structures and how they are put together," co-author Arthur Ragauskas of Georgia Institute of Technology said.

"This paper illustrates that you need to use an holistic, integrated approach to study the totality of recalcitrance."

Using the current study as a model, the researchers are extending their investigation of tension wood down to the molecular level and hope to eventually unearth the genetic basis behind its desirable physical features.

Although tension wood itself is not considered to be a viable feedstock option, insight gleaned from studying its unique physical and molecular characteristics could be used to design and select more suitably tailored bioenergy crops.

"This study exemplifies how the integrated model of BESC can bring together such unique research expertise," BESC director Paul Gilna said.

"The experimental design in itself is reflective of the multidisciplinary nature of a DOE Bioenergy Research Center."

The research team also includes Georgia Institute of Technology's Marcus Foston, Chris Hubbell, Reichel Sameul, Seokwon Jung and Hu Fan; National Renewable Energy Laboratory's Robert Sykes, Shi-You Ding, Yining Zeng, Erica Gjersing and Mark Davis, and ORNL's Sara Jawdy and Gerald Tuskan.

BESC is one of three DOE Bioenergy Research Centers established by the DOE's Office of Science in 2007. The centres support multidisciplinary, multi-institutional research teams pursuing the fundamental scientific breakthroughs needed to make production of cellulosic biofuels, or biofuels from non-food plant fibre, cost-effective on a national scale.