In order to overcome the problem, engineers put expansion joints in the bridge to absorb these changes.

However, when it comes to railway bridges, this problem compounds as the expansion of a mile long section of rail could be as much as 1.5m over a temperature change in some climates of 37.7°C. This could lead to rail buckling, known in the industry as "sun kink" (Figure 1) — and the derailment of a train.

Improvements in steel tracks have evolved over the years. Prestressing techniques are used with rails and joints to help control the effects of expansion and contraction. However many railway companies and mass transit agencies are taking the solution to the bridge expansion /contraction problem a step further by installing measurement devices on the bridges themselves to find out how much the bridge has moved, and to be able to determine if any structural problems exist or if any track shifting has actually taken place.

By knowing that tracks have buckled or kinked, railway companies can divert trains and repair track problems before an incident takes place.

There are over 20 railroad bridges in Australia, and each bridge is required to be inspected every year, but these inspections are done largely on a visual basis.

LV-45 series linear sensors, of which Bestech Australia is a supplier, are being used to measure bridge movements and to conduct road and rail bridge monitoring.

The LV-45 sensor is designed to survive elements like high humidity, blowing snow, and driving rain over a wide range of temperatures (-40 to 100°C), as well as withstanding the inherent shocks and vibration from a train.

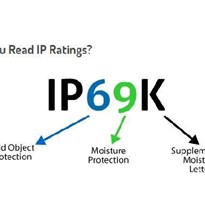

The LV-45 series housing is rated IP67 and is offered with various connector and cable terminations to suit virtually any environment.

As in the shown above (Figure 2), as a pier-to-bridge interface measurement application the LV-45 sensors are hard fixed to the pier and to the bridge where ball joint swivel rodends are used to take up any misalignment during initial installation.

The system can measure position changes in all three axes and can track those changes over time to show short and long term trends and highlight potential problems or incipient failures before they take place.