Bürkert, a specialist in process control solutions, explains what should be considered in the selection process – with a focus on the chemical resistance of various components.

Selection of valves for any given application is no trivial task.

A valve in a brewery can be very different to one used in a pharmaceutical application for example; one of the critical aspects of valve design is the chemical resistance properties of the valve housing and the gasket materials in relation to the substances which it is expected to control. A long and trouble-free service can only be expected if the correct materials have been selected in the design process.

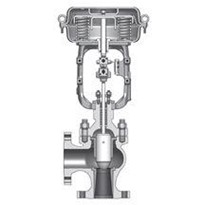

In the case of a simple solenoid valve, many of the components, such as the plunger, return spring and seals are all exposed to the media. Information on the chemical compounds, temperature and pressure are all necessary to make an informed material selection.

If the production process involves liquid food products, the plastics and elastomers used should also conform to the local food and hygiene regulations. In addition, some processes require a cleaning cycle to be performed in-between production processes, which requires data that furthermore ensures no undue material degradation.

Factors such as mechanical loading, increased temperatures and chemical concentrations all have a bearing on the performance of individual components, which can be manufactured from a range of materials. In general the valve bodies are made from either brass or stainless steel with some being constructed from Polyamide.

The type of valve most appropriate for each application is governed by a number of factors, but in general: plunger-type direct acting valves are best suited to neutral and clean fluids; while pivoted armature valves offer improved reliability by employing a media separating membrane to control corrosive, contaminated or aggressive fluids.

The range of options for sealing and separating membranes is quite extensive with each having benefits and drawbacks. The combination of chemical compound, temperature, pressure and cost all have influence in this design decision.

Below are some of the more common compounds in use with brief descriptions of their properties.

PTFE (Polytetrafluoroethylene)

PTFE is almost totally insoluble and chemically inert. It has a high temperature resistance and PTFE ball valve seats, because of their natural lubricity, require no lubrication. PTFE diaphragms and flange gaskets are used in the most severe chemical resistance applications.

EPDM (Ethylene Propylene Terpolymer)

EPDM is a synthetic rubber used as the standard seal material for many valves. It is the most economical choice of elastomer and has excellent chemical resistance to acids, alkalis, salts and many others at temperatures up to 90°C. However, it is not suitable for use with oils, petrochemicals and concentrated acids.

NBR (Nitrile rubber)

NBR has a high chemical resistance to oil and petroleum but is weak on oxidising media such as acids. Nitrile also has excellent abrasion resistance and is less expensive than FKM and FFKM.

FKM (Fluorinated elastomer) and perfluoro-elastomers (FFKM)

These are more expensive than neoprene and nitrile elastomers because they provide additional temperature and chemical resistance. Certain grades of FFKM can perform continuously at temperatures above 200°C.

PPS (Polyphenyl sulphide)

PPS is a high performance thermoplastic used in many engineering applications. With the ability to perform above 200°C and with resistance to acids and alkalis as well as abrasion, PPS can be selected as a valve body material.

PVDF (Polyvinylidene fluoride)

PVDF is resistant to solvents, acids and bases, making it an ideal material for the valve body where high temperature resistance is not required. A very flexible product, it can be injected, moulded and welded, making for easier manufacturing of the valve bodies.

PEEK (Polyether ether ketone)

PEEK has excellent mechanical and chemical properties but is susceptible to high concentrations of sulphuric and nitric acid. This improved performance accounts for a higher price but provides superior qualities for valve bodies.

-205x205.jpg)