The Prospect Awards are the largest national mining awards, and recognise industry leaders in safety, technology and innovation. This year they were held at the Sofitel in Sydney's CBD and hosted by TV personality Rob Carlton.

"It was great to be recognised amongst industry leaders for our innovations – it reflects the hard work and dedication put in by the whole team at Air Springs," says James Maslin, National Sales and Marketing Manager, Air Springs Supply.

"Actuators may be small when compared to large mining equipment, but the difference they can make to the smooth running of larger machinery can make a large impact," he said.

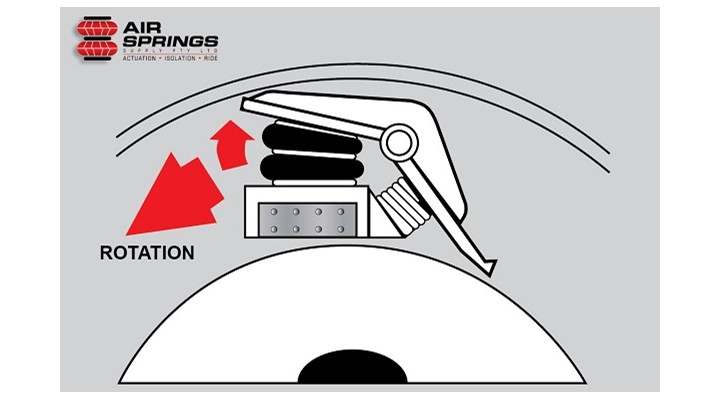

Belt Scraper Actuators

A simply engineered alternative to metal springs or torsion bars from Air Springs Supply Pty Ltd helps to prevent breakdowns of mineral and industrial processing belt scrapers and to extend the life and productivity of entire belt systems.

Flexible pneumatic Airstroke® air spring actuators from Firestone – including compact and easily installed Style 16 types – adjust to different load requirements simply by varying the air pressure contained within them.

These tough rubber-and-fabric bellows (identical in construction to the airbags proven in truck and train suspensions) are suitable for applications requiring flexible force and continuously supple performance to flex with irregular loads.

"Airstroke air springs provide force evenly over the surface upon which they are acting, rather than imposing sharp point loads. Further, they will undulate over irregular loads passing beneath them, flexing with the load profile if necessary, rather than fighting irregularities in the load and causing jerking, jamming and strain on the production line," says Maslin.

By preventing material buildup, belt scrapers help keep the belt from drifting off track, prevent erratic loads on the motor, eliminate uneven wear on pulley bearings and damage to return idlers, as well as helping to minimize belt stretching.

Suitable for uses as diverse as fine food and pharmaceutical production, through to mineral processing and bulk material handling, air springs also have another major advantage for design engineers: the ability to rotate through an angle without a clevis. In addition to making air springs easy to install in compact spaces, this ability to bend with load (and to tolerate side loadings within certain limits) means the air springs will perform where more rigid alternatives would break or wear.