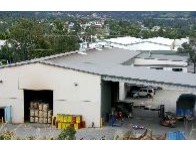

Australian Overseas Alloys, which is pushing into the WA mining and quarry market to complement an existing global customer base, re-engineered its air flow system to ensure optimum conditions throughout a 24-hour operation that includes a lot of welding and hard facing processes.

The new fan driven system from Fanquip regulates air flow within two sections of the company's large premises: the main manufacturing area and a smaller, yet vital, section containing welding equipment power sources.

Wear Plate Manager at Australian Overseas Alloys (AOA), Paul Christie, says the company routinely upgrades all aspects of its OH&S systems and the introduction of a fan driven system was seen as the best solution for its 24/7 production.

"A lot of hot welding activity and plasma cutting is now a mainstay of our business, so to remain ahead of any potential heat-related problems we organised a solution that provides the best ventilation," said Mr Christie.

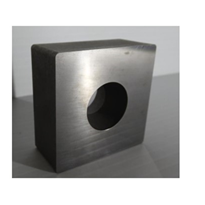

"We manufacture chrome carbide wear plate for hoppers, bins, chutes and slurry pipes that resist wear in mining industry and general industrial applications.

"The associated processes are often heat intensive, yet we have managed to create a comfortable and safe work environment utilising the power of air movement with a system of strategically located fans."

The fan system was supplied and fitted predominantly onto the roof of the premises by Australian manufacturer, Fanquip.

To control the potential for heat build-up in the manufacturing plant, Fanquip engineers installed three 1200mm-diameter vertical discharge fans to safely expel the non-toxic heat.

Not only were these three items fitted at specific positions, they also were supplied with a corrugated iron integral base to match AOA's existing roof profile.

Apart from corrugated iron, Fanquip's roof fans have various base profile options: Trimdek, Super Six, Spandek, Double Rim & Span 4, and Longspan.

By allocating specific mounting points on the roof footprint, the fan specialist was able to achieve an optimised air flow to create a constant breeze effect in the workplace.

In the adjacent welding machine power source enclosure, Fanquip installed a 1500mm diameter wall plate fan to expel the heat expected from such equipment.

A wide ducting system above the power sources captures the heated air as soon as it is generated and directs it through the wall plate fan into the external atmosphere.

"By adding a fan-driven ventilation system to our premises we not only keep ahead of potential OH&S concerns, we have optimised our premises to meet our target markets with the best equipment possible," said Mr Christie.

"Currently, we do a lot of work on the Australian eastern seaboard and export to Asia, India, the USA and other parts of the world.

"Now we are totally prepared to push into the WA mining industry."

AOA's products are:

* Pre-deposited abrasion resisting plate. AOA 2360 MKII and AOA 2355 grade chromium carbide clad wear plate.

* Tubular hard facing welding electrodes. AOA anti-wear hardfacing electrodes.