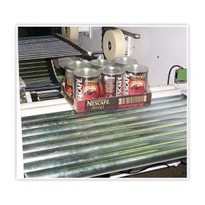

In 1995 the JR Simplot Company acquired some of Australia's favourite food brand businesses including Edgell, Chiko, Birds Yes, Harvest, Plumrose, and Leggo's. The Simplot Ulverstone plant produces potato based products for the frozen and fast food industries for Australia, including frozen french fries, hash browns and dehydrated potato products.

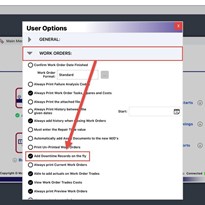

Grant Rodman, from the Simplot Ulverstone plant, used to write over 1,000 work orders a year. Over a quarter of these were Preventative Maintenance tasks, parts and requirements of each job had to be included manually. It was time consuming and there was no processed data received back from the work done, due to lack of labour and time. This was resulting in little control over expenses, very little analysis and poor recording of what was and what needed to be done.

MEX was not Simplot’s first choice in a CMMS, but as they only had a limited budget, MEX small price was difficult to ignore. MEX was prejudged as a limited functionality CMMS system that could be thrown out if it was deemed impractical.

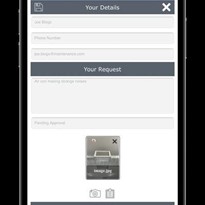

Simplot viewed MEX as being very easy to use, and liked that they could customise their work orders. No other CMMS's allow for this range of flexibility.

Simplot ultimately needed a CMMS to work smoothly and efficiently and MEX was able to help. Work Orders were able to look the same, which made switching over from paper easy.

What results have you got from MEX?

Nowadays, MEX has gone from being a quick introduction of a CMMS for Ulverstone the Tasmania Plant, to being used in all Simplot Plants Australia wide. The reason why is because MEX works.

MEX may be a low cost system, but it packs a lot of punch. Grant Rodman says "It is just easy to use, and makes us more efficient." From the humble beginnings of the purchase of MEX, it has gone on to become a standard within Simplot Australia.

The Ulverstone plant now produces 8000 work orders annually. The stores inventory of 7,800 items is predominately managed by MEX. The variance achieved at stocktake is as low as 2% and Preventative Maintenance has increased from 25% to 35%. Most importantly, management can see where maintenance money is spent and there are comprehensive records of all work done.

MEX was accepted at the Ulverstone Plant due to its ease of use and superior functionality.

What would you do differently if you had to do this again?

Grant Rodman's only suggestion is to "make sure you do the stores catalogue first". It was not until 2 years after their initial purchase of MEX that they implemented the stores package. He realised after this that by having the stores systems up and running, that it added real meaning to the work orders. It helped the tradespeople out by letting them know what parts, if they were available and where to find them. Grant says that "the benefits of using MEX really increased when the inventory part of MEX was implemented."

With the Stores catalogue in place, Grant and the team at Simplot can plan the up coming work effectively, by being able to produce part lists from the PM schedule well into the future.

What is the best thing about MEX?

"MEX is very user friendly and has a good structural flow," said Grant. Grant has had numerous staff over the years on light duties who have picked up the use of MEX in less than an hour. "They are shown once, and then they pick it up right away."

What pearls of wisdom do you have about Computerised Maintenance Management Systems?

"Keep it simple stupid," said Grant. "The easier the system is to use, the greater the chance of it working for you."

-205x205.jpg)