Through ongoing service to the energy and chemical sectors, Cootes has established a reputation for rigorous adherence to safety standards.

Being a company committed to the highest levels of customer service, Cootes recently recognised the need to update its paper-based delivery management system.

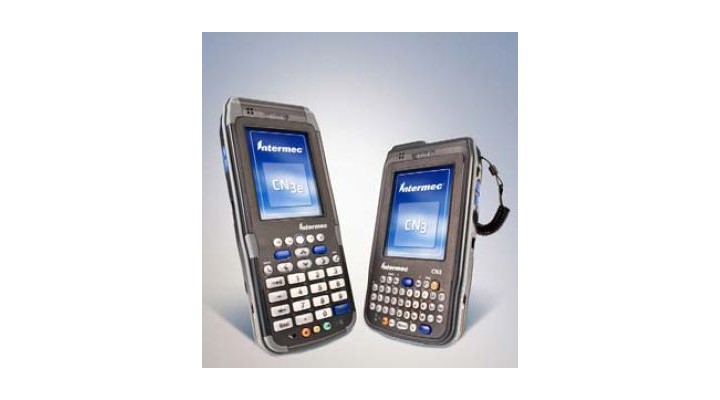

After consultation with software developer InterDev Systems, and leading Intermec partner and systems integrator, Gamma Solutions, Cootes adopted Intermec's highly versatile, rugged CN3 hand-held computer coupled with InterDev's Xmotion Transporta System to reduce paperwork, provide real-time information and improve delivery tracking.

The challenge

Cootes works with some of the biggest chemical and resource companies in Australia including BP, Caltex, Elgas, ExxonMobil, Origin Energy, Shell, and Vitalgas to transport potentially dangerous goods, safely.

Until recently, Cootes was relying solely upon a paper-based delivery system for both drivers and back office staff to manage deliveries for these customers. This system often resulted in lengthy delays as drivers had been required to pick up their manifest (driver worksheets) from the contract manager at the depot, complete each of their assigned deliveries and then hand write all relevant information. As pick-up and delivery points can often be several hours drive from the depot, the existing system relied on the driver to personally bring back the day's paperwork and place it on the appropriate office staff member's desk.

As well as obvious risks, such as paperwork being lost or misplaced and delays in data entry into the system, this paper-based method often meant that invoices could take days to go out and staff would often have to spend equally as long completing any number of outstanding manifests. Due to the highly dangerous nature of the material that Cootes Transport Group specialises in, this additional paperwork also added unnecessary stress to drivers.

Streamlining the process and minimising the risks

In order to streamline Cootes' existing delivery management system, and enhance customer service levels, Cootes commissioned specialist provider of mobility solutions, enterprise integration and software application developer, InterDev, to design and construct a handheld solution to enable paperless operations.

After researching the hardware available to the Australian market, Interdev produced a custom version of the Xmotion Transporta system for Cootes, and coupled this with the world's smallest, most advanced rugged handheld computer, the Intermec CN3 hand-held computer, to allow real-time status reporting and improved delivery management.

Through selecting Intermec's versatile CN3 hand-held computer to be used within the truck cabins, Interdev was able to develop an application that would easily integrate with Cootes' existing Freight2020 Transport Management Application to create an all-encompassing freight delivery system. Freight 2020 is a complete package that encompasses Financials, Operations and Workshop modules.

Using the operations module, Cootes' delivery bookings are created and allocated to a Manifest. The bookings can be manually entered or derived from an electronic import sent to Cootes by some of their larger customers.

The Manifest has a prime mover, trailer and driver allocated to it when created, before the scheduling of it is completed. The custom written Business Rule Layer polls this table every 60 seconds to check for manifests. This area is updated nightly automatically with any new rules that have been defined throughout the day such as new drop points and are made available to drivers through Intermec's CN3 in the truck cabins.

Due to the highly versatile platform Intermec's CN3 hand-held computer offers to the transport and logistics sector, Interdev was able to configure the Xmotion Transporta software for Cootes that actually replicated the required fields for the Frieght2020 onto the CN3 handheld device.

Transporta, which is web based, interfaces directly with a Business Rules Layer to route the manifest onto a handheld for the driver. This routing is carried out by some rules that have been predefined matching a Prime Mover to an Intermec CN3 handheld.

These relationships are editable, enabling Intermec's rugged CN3 hand-held computer's to be allocated to alternative Prime Movers if the need arises. The driver and contract manager are then thoroughly trained in completing a manifest on the Intermec CN3 handheld and coping with any eventualities that may occur.

Intermec's CN3 also provides the driver with the updates at each point of their journey, with a log being visible on the CN3 via the Transporta software used by the contract managers. One of the biggest obstacles, in Australia, to real-time data transmission is the vast distance that drivers may have to travel in order to make their deliveries on time.

To combat this, without using an expensive nationwide network, Cootes is employing Intermec's advanced CN3 hardware coupled with the Xmotion Transporta system over a standard GSM/GPRS mobile phone network, to allow data to be stored on the hand-held and automatically uploaded as soon as the truck is back within range.

Upon completion of the trip, the driver acknowledges a "Complete" request on the Intermec CN3 handheld, which sends the manifest to the 'GatewayInManifest' Table where the Business Rule Layer again routes it back to Freight2020. A copy is left in the 'GatewayInManifest' Table and the original manifest created in Freight2020 is updated.

Through using Intermec's advanced CN3 hand-held computer coupled with Interdev's Xmotion Transporta system, Cootes' invoicing can be done within hours instead of days and staff, that were once completing manifests all day, can now carry out other tasks within the business.

Future-proofing the solution

While the current application of the Xmotion Transporta system coupled with Intermec's CN3 hand-held computers enables Cootes to ensure safety and compliance through effective break management, whereby drivers are advised via their in-cabin CN3 when they are legally required to stop for a rest break, there is the potential for Cootes to experience greater future benefit with the new delivery management system.

With the combined Intermec and Interdev Xmotion technology being employed by Cootes, the company stands to gain improvements in its delivery management systems that will only increase over time due to the unique sitemaps being constantly improved by driver input. In fact, the CN3 and Xmotion Transporta systems are driven by these forms of input.

Intermec's powerful CN3 hand-held computer provides drivers with the ability to receive directions, view site maps (which instruct drivers on their delivery points), receive instructions on site hazards (via Text to Speech capabilities) and the ability for drivers and contract managers to send notes to each other (whilst the vehicle is not in operation as there are zero phone tolerance rules in place whilst driving.)

These functions will only continue to strengthen with time as drivers are able to make notes with the in-cabin Intermec CN3's and record areas with low hanging wires, dangerous black-spots, changes in speed limits or which routes have high traffic levels.

Importantly, this vital information is then made available to all drivers in the fleet via the in-cabin range of Intermec CN3's, to assist them in planning the most effective route to their delivery point.

In line with IES standards and Cootes commitment to safety, Intermec's CN3 hand-held computers also interface to MinorPlanet's vehicle tracking system.

Additional software from Smart Car Technologies called SpeedAlert warns drivers when they are exceeding the speed limit, even sending an alert via the truck's in-cabin speakers that overrides any music or radio interference to get the point across without confusing the driver.

Additionally, this software used by Cootes is coupled with GPS and intelligent enough to activate during limited speed time zones – such as those found during the beginning and end of school operating hours.

The use of Intermec's CN3 in comnjuction with GPS services has also provided the basis for a powerful enhancement to the Xmotion Transporta solution. The enhancement known as 'Phone Control' ensures that the phone function of the CN3 is disabled when the vehicle is detected as being 'in motion'.

Once the vehicle is stopped, the phone is re-activated allowing safe use of the mobile phone functions. When calls are reveived while the vehicle is in motion, calls are diverted to voicemail which are automatically played when the vehicle is stopped and any SMS messages are played back using Text to Speech.

Cootes, Interdev, Gamma Solutions and Intermec – market Leaders

Leading Intermec partner and systems integrator Gamma Solutions fulfilled an essential role for Cootes by providing all hardware for the installations outside of the MinorPlanet configuration.

IES ensured the project's systems integration and delivery, as well as ensuring all hardware elements functioned adequately. They also provided driver training and support in addition to Gamma Solutions technology backup across the country.

By employing Interdev and Intermec's advanced delivery management solutions, Cootes' is demonstrating the company's dedication to OHandS, though speed monitoring and ensuring that each and every driver must take their legislative rest breaks, as well as illustrating their commitment to customers through the strategic investment in new technology to improve their accuracy of their deliveries.

According to IES Group Process Development Manager Brett Wilson, Intermec's CN3 hand-held computer was the ideal solution for Cootes because, "We did a thorough market analysis as to what was on offer and confirmed the Intermec CN3's ability to offer greater RAM capabilities with our growing safety and compliance features in the software and rugged design to ensure durability in the environments it is operating."

As a result of Interdev coupling their Xmotion Transporta software with the advanced Intermec CN3 hand-held computer, Cootes has been provided with a powerful paperless environment capable of real-time data transmission.

By streamlining their existing delivery management system with Interdev and Intermec, Cootes can expect their safety record and customer satisfaction levels to continually improve into the future.