The flow drilling process can form the thread directly in the displaced drilled material, thereby making this additional operation unnecessary.

SUHNER and Flowdrill are collaborating in this field of specialised technology. Thermal flow drilling uses a Flowdrill-tool to produce passages several times the thickness of the thin walled material.

Core drilled holes formed with this method are essentially more precise than threads formed with conventional means. Moreover, this process, by forming the existing workpiece, saves time and material.

Flow drilling is based on a combination of axial force and relatively high speed that generates local heat through friction. This friction heat and high surface pressure cause the material to undergo plastic deformation. The special geometry of the tool and its special hard metal allow it to pass through the material in one operation.

The flow drilling process

1. Starting phase

- Crater shaped indentation around the tool tip

- Axial force raised to the maximum

- Material displaced counter to the feed direction

2. Material flow phase

- Wart shaped bulging on the bottom side

- Axial force reduced

- Torque raised to the maximum

3. Forming phase

- Forming of the bush

- Collar shaped according to the tool type. Either as an edge in the form of an O ring or as a plain surface.

This bush made without chips in seconds can be used as a bearing, as a load bearing soldered or welded connection, or of course as a core hole sleeve for screw unions. In contrast to other processes, flow drilling induces material hardening for high tightening torques in threads and large load bearing capacities in bearing bushes. Flow drilling tools are available for diameters of 1.5–46.0 mm.

SUHNER can offer for this work a range of drilling units with various feeding systems. The classical flow drilling units are the BEM 12 and the BEM 20, each with pneumohydraulic feed, i.e. a pneumatic feed regulated with a hydraulic cushioning cylinder.

The following series of operations are implemented in practice

1. The spindle moves the rotating flow drill in rapid traverse directly in front of the workpiece.

2. Now under regulated, but still rapid feed, the tool tip contacts the workpiece.

3. Under the action of friction, the material glows and starts to flow.

4. The feed movement, first obstructed by the contact, now continues, i.e. the spindle presses the flow drill through the material. The characteristic collar is formed.

With this method, the flow process defines the spindle's feed movement. The alternative to the pneumatic machining unit takes the form of CNC units. In this case, SUHNER offers with its BEA 25 CNC a powerful machining unit with integrated recirculating ball screw and servo motor drive. With this process, CNC programming can optimise the sequences named above to the tool and workpiece.

The collar made by flow drilling is now ideal for thread forming.

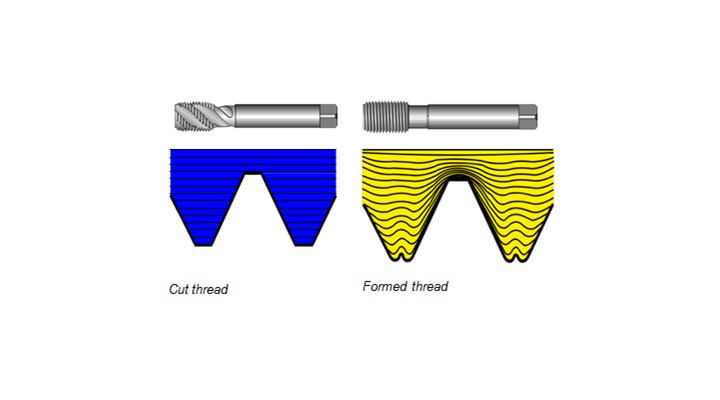

Thread forming

In contrast to conventional thread cutting, thread forming in connection with flow drilling presents huge advantages.

The preceding warm displacement of material during flow drilling and the subsequent cold rolling during thread forming cause the material to undergo intense hardening. This results in threaded connections with high pullout strengths.

The chipless thread former can work at essentially higher speeds and exhibits an extremely long service life for enhanced productivity.

Owing to the displacement the material is forced to flow. This gives rise to a compressed thread profile.

When the threads are formed, their highest points are pressed into the material. The material is deformed and flows into the gaps between the thread former's teeth.

There are no chips.

Advantages of thread forming at a glance

- No chips

- Thread depths up to 4 x D possible

- Essentially lower roughness height in the thread flanks than with thread cutting

- Approx 20 % greater pullout strength under static load

- More than double the fatigue limit under dynamic load

- Thread formers not liable to break, so maximised machining reliability

- Considerably higher service life than taps, particularly when thread pitches ≤ 1.5 mm

- Approx 65 % of all industrial machined materials can be formed: steel up to 1200 N/mm², stainless and acid resistant steel, copper and copper alloys, aluminium and aluminium alloys.