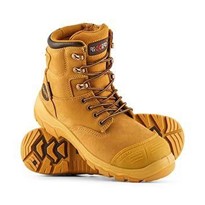

Steel Blue is Australia's largest manufacturer of safety footwear. The company has experienced strong growth since operations began in 1995 with the launch of the first Steel Blue products. More recently the company has introduced the Howler brand of footwear into Asia and South Africa.

Steel Blue's goal is to manufacture and market the most comfortable safety footwear and safety boots in the world. The company prioritises the research and development of new cutting edge products, technology and customer service to expand the business into a world-class company.

In 2001, the company moved to larger premises in Malaga, Perth, to meet the growing demand for their products as they expanded their national and export markets and increased their local market share.

"We produce around 180 to 200 pairs of boots a day in our Malaga factory in Perth," said Halikis.

"We went live two years ago with Epicor ERP for Manufacturing. Although Epicor is only implemented in Perth, we also have a number of factories in Jakarta. We sell into the Australian, New Zealand and Asian markets, and we are about to enter the South African market."

Using Epicor material requirements planning to increase efficiencies in production

The Epicor enterprise resource planning (ERP) solution for manufacturing features strong material requirements planning (MRP), capabilities and enables an organisation to plan, schedule, execute and monitor its entire manufacturing business. From raw materials to final product, Epicor ERP provides a greater level of flexibility and agility.

"Apart from the core production management manufacturing module we use Epicor ERP for finance, sales and material management," said Halikis.

"We manufacture a range of boots with different styles and classes. Based on colour and size we have around 8,000 SKUs (stock keeping units). Each boot has a different bill of material (BOM) and that is where our costs are captured by Epicor."

Halikis explained Steel Blue's manufacturing process: "We use MRP to create the demand – Epicor prints out the job traveller which goes to the floor and goes through the manufacturing process from start to finish. Once the boots are boxed we go into time and expense entry and submit and close the ticket. Our manufacturing manager uses Epicor to run dashboards and reports to manage materials and BOM. We run MRP once a week and it allows us to plan our production seven days ahead. It makes the system more efficient."

Cutting costs and saving time through supply chain and third-party logistics management

One of the biggest benefits identified by Steel Blue is the role Epicor plays in supporting the company's supply chain management. Epicor helps achieve supply chain visibility and remove processes that do not add value. It equips manufacturers to meet customer demands for faster delivery and lower cost by synchronising processes within and outside the company.

Halikis also discussed managing the company's third-party logistics (3PL) provider with Epicor ERP.

"Manufacturing is a large part of what we do; however, from a logistics point of view the material management functionality is very important. We have a lot of stock in Perth and we opened up a 3PL in Brisbane to service our East coast customers.

"We manage our 3PL relationship through Epicor and it helps us to cut costs with shipping. It has saved us a lot of time and improved efficiency. It used to take us five to seven days to get stock from Perth to Brisbane, where as now it takes us two to four days. We also use Epicor to manage our stock levels and get insight into what type of stock is coming out of Brisbane to our East coast customers," she said.

Additionally, Epicor integrates with Steel Blue's 3PL warehouse partners for outsourced warehouse management.

"We created a new plant in Epicor for the 3PL and we put a couple of BPMs (business process management) into the system based on certain criteria of where the customer is located and which plant the stock will come from.

"We then run the fulfilment workbench, reserve and release and the Epicor system automatically sends out an EDI (electronic data interchange) file order to our 3PL provider and they pick it, pack and send it. Epicor creates an invoice and sends it straight to the customer via email," says Halikis.

With Epicor ERP, Steel Blue has streamlined manufacturing, supplier relationships, gained efficiencies and increased visibility across the organisation.

-160x160-state_article-rel-cat.png)