In association with the Finish developer and manufacturer EVAC, our Environmental Solutions section now has the perfect system to treat waste water in commercial sea vessels, offshore rigs, ferries, navy ships and the general boating market.

Known as the EVAC Membrane Bio-Reactor, this system utilizes the tried and tested biological treatment process combined with modern membrane technology to separate the water from the nasty stuff and doing it so well that what we return to the ocean is so good you could drink it (not that we’ve tried!).

EVAC have however completed testing against the demanding MPEC.159(55) standard, where the discharge water is tested over 10 days in real life application and the Membrane Bio-Reactor passed with flying colours, meeting all current and future cleanliness standards.

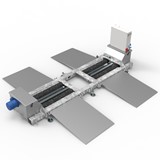

EVAC not only worked hard on the output from the MBR, they also spent many years in design and testing to ensure that the EVAC name was on the best available product. The use of flat plate membranes manufactured by Kubota, the worlds leading membrane supplier into the sewage industry, was the final answer.

These flat plates filter the water from the waste and because they require very little pressure to get the water out, they last a very long time, require very little power to run, allow the biological process to work at its best and are very hard to block.

EVAC also worked hard on ensuring the process was reliable whilst also meeting the tight space constraints on all types of commercial vessels. Industrial pumps, blowers and filtration units are combined with industrial PLC control units to ensure 24/7 availability.

The system does not require any back flushing or constant chemical cleaning, making it the most economic and maintenance-friendly membrane bio-reactor solution on the market.

The Membrane Bio-Reactor system is now available in standard configurations, with the smallest able to treat waste from 24 crew and passengers but it can be scaled up to fit the worlds largest cruise vessels with over 5000 people onboard.

So successful is the system that EVAC has been selected to supply the advanced total waste water treatment system for eight FREMM multi-mission frigates of the French Navy, which will enter service in 2011 through to 2016. H.I.Fraser is currently working with both the AWD and LHD projects to examine the opportunity for both projects to take advantage of the technology so that the AWD and LHD are fully MARPOL 2010, MPEC 159(55) and DEFAUST 5000 compliant.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)