With a rich product line that includes LED flashlights, camping lights, bicycle lights and table and bedtime lamps, the company is always in search of new, compelling product designs.

On average, Lord Benex launches 15-20 innovative, multi-functional products each year.

This imposes challenging prototyping demands on its R&D group.

The challenge

Lord Benex's product development process used to begin with sending 3D design files from Taiwan to rapid prototyping outsourcing partners in China. This often entailed long delivery times and resulted in delayed development schedules.

"In addition to schedule delays, there was also the issue of model accuracy, which never quite met our standards. However, our top concern has always been confidentiality," Li-wen Song, chairman of Lord Benex, said.

"We were always anxious that new product designs might leak out to competitors."

The solution

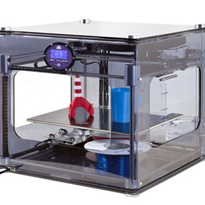

Lord Benex decided to replace contracted rapid prototyping with in-house 3D printing. It considered several 3D printer brands before finally deciding on the Objet Eden260V 3D Printer.

"One of our most basic requirements was rubberlike materials, so that we could test friction resistance in models," Song said.

"The Objet Eden 3D Printer answered that need with a rich selection of materials and varying grades of soft rubber."

The ability to print with translucent material to simulate the glass and plastic lenses of lighting fixtures was an additional factor that swayed Lord Benex toward Objet.

In addition, the company was impressed by the Objet Printer's high resolution printing and the smooth exterior and interior surfaces of the Objet models, which are both important for Lord Benex's lighting products.

The value

Using the Objet Eden260V 3D Printer, Lord Benex is now able to confirm mould appearances, conduct assembly and structural testing, and perform complete verification of product designs before production.

The in-house Objet 3D Printer is also used to produce small parts of the final lighting products. The team then assembles the parts to create a complete 3D prototype, which is then painted, and run through structural and functional testing till final confirmation.

"Overall, the Objet 3D Printer for rapid prototyping has greatly improved our development timeline, and placed us at a completely different level in terms of our design and verification process," Song said.

With new product production becoming faster and more reliable, Lord Benex has also noticed the improved satisfaction of the company's customers. Clients can preview tangible models early in the process, provide feedback, and are more confident about the final product design.

Last but not least, is the confidentiality issue, which was resolved by switching to in-house 3D printing.

Song concluded: "It has completely eliminated our concerns about losing our competitive edge by not properly guarding our innovative designs."

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)