This situation can be attributed to traditions, transport logistics and production sequences that, due to existing structures, have developed over a period of years, as well as to the multitude of concrete reinforcing steel diameters that have to be processed.

Not much has changed in terms of production sequences since the time when processing reinforcement steel was transferred from building sites to efficiently structured business operations.

These were able to enhance efficiency by means of improved work preparation, automated stirrup benders and automatic rod cutting machines. To all intents and purposes, the actual material flow has remained unchanged.

This is the reason why, in most companies, rod cutters can be found that travel transversely in front of a rod storage unit containing reinforcing steel sorted by diameter and length. The steel is then drawn out of this rod storage unit.

Even if structures have been, and will be further, changed on account of the increase in processing round material, cutting steel from rods is an important consideration in cost effec- tiveness for any company handling concrete reinforcing steel. Besides this, rod material is cheaper than round material.

This advantage in price can play an important role when deciding on a manufacturing system. Mobile rebar cutting machines still occupy a key position as they are the pulse generators for processing machines down line and thus of vital importance for overall operational output.

Metax rebar shearing machines

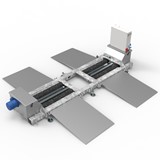

Metax rebar shearing machines can currently look back on a development history of 34 years. Metax rebar shearing machines work very effectively and rapidly. They are capable of high performance over the entire range of diameters - something made possible by a 140mm cutting width. Exceptionally great output can be achieved even in the lower diameter range because several rods can be cut simultaneously and cleanly alongside each other.

The measurement and pull-in system works safely and with great precision. Measurement is carried out without stops. The pull-in speed is about 150 m/min. The rods are held tidily and securely under tension by means of a chain system with rubber-coated studs. This means that the machine can run at high acceleration rates even with short lengths.

The good cutting performance is attained by means of an especially robust hydraulic shear. Measurement sections above the nominal value can also be generated due to the stopless pull-in measurement system. This is made possible by providing support for the machine with a channel extension and, in this mode for example, it can cut lengths of more than 16m.

Pedax has optimised this successful range. It now works more precisely, more rapidly and more quietly with appreciably lower energy consumption.

Individual model designs

Cutting performance and pull-in speed are important for production output. Non-productive time, occasioned by transverse and distribution movements, is of particular significance. In this case, it is essential to make use of reserves and Pedax has developed a system design that factors in individual production requirements.

A distinction is generally drawn between two model designs, which can be supplied with two, three or even six transport channels. With the first version, the rods are rolled into their predetermined channel directly after cutting.

In the second case, the rods are collected in a separate channel after being cut and then, by means of hydraulic stops, set into a predefined channel position in which several cycles can be collected. This means that production can continue without interruption for a longer time.

In addition the sheared rods are positioned nicely flush to their bending lines, just as the bending machine needs them. This does away with any laborious turning and sorting procedures. Most companies decide on this model design because the additional flexibility is quickly paid back by reduced non-productive times.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)

-205x205.jpg)

-205x205.jpg)