Of course if the compressor is quite new or has not done many operational hours then the decision is usually

straight forward - repair. However if the compressor is getting on a bit or has done many operational hours,

then the decision is more complicated.

There are several other factors to consider in making the decision:

- How critical is the compressor to your day to day business?

- How often is the compressor used?

- How long can you afford to be without ‘air’?

- Has the current compressor been regularly maintained?

- What are your future compressed air needs?

A critical factor is reliability of the current compressor and this is directly related to how well it has been

maintained and how many hours it has accumulated. Well maintained compressors can run trouble free

for many thousands of hours before needing a major overhaul.

Regular servicing should include not just basic consumable parts such as filters and oil but also preventative maintenance parts such as valves and solenoids. Your Sullair Service representative can advise you on the correct service regime for your machine.

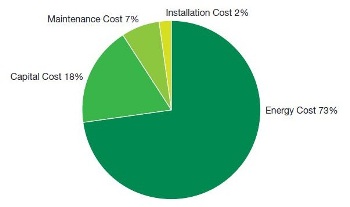

In addition, it is essential to consider the electricity consumption between operating an old vs. new compressor

over the life of the compressor.

- Compressed air systems use up to 10% of total industrial electricity use in Australia.

- Often an air compressor is the largest single source of energy consumption in a manufacturing facility.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)