MAXI-TUBE® is an innovative Zinc –Alloy coated steel section which provides high corrosion resistance in many aggressive environments. It’s benefits include:

- A slower corrosion rate than Zinc coated steel

- It is suited for coastal, industrial, intensive farming, food processing and infrastructure applications.

- It has good paint and powder coat adhesion, plus displays a high quality surface finish.

- Lead times may be reduced by eliminating steps from traditional coating processes.

- It achieves life cycle and maintenance cost benefits

- It is available with a defined warranty.

- A coating harder than galvanised steel which delivers superior scratch resistance

- It has an aesthetically pleasing mill finish with zero spangle and a smooth satin coating.

- It demonstrates good weldability for ease of fabrication.

Australian steel, tube and pipe manufacturer Orrcon Steel engaged MSSA to develop a quality weld zone coating system that provided the equivalent galvanic protection to that of MAXI-TUBE.

Using Arcspray technology, MSSA Engineers formulated a coating that is able to be applied in the production line on the mill to restore the life expectancy of the original tube.

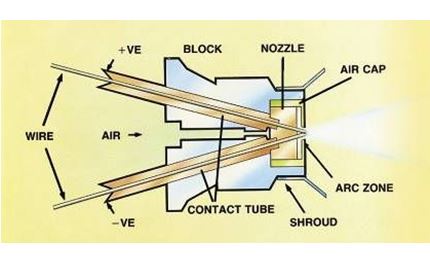

In the Arcspray process, two electrically charged wires are driven and guided so that they converge at a point and form an arc. An air nozzle atomises the molten metal produced and propels it towards the work piece.

To find out more about MAXI-TUBE® visit www.maxitube.com.au

For further information on the thermal spray process, please contact Metal Spray Supplies Australia (07) 3823 1004/ Fax (07) 3823 1005/e-mail [email protected]