Mipac scope:

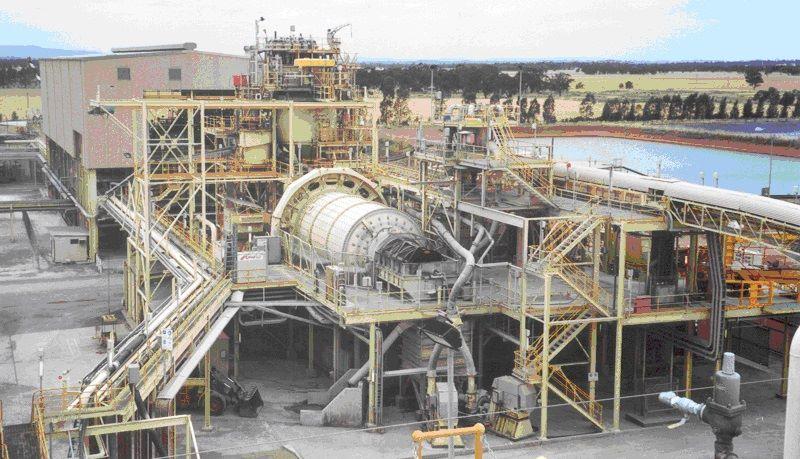

- Design, specification, configuration and commissioning of full plant-wide control system for the upgraded smelter. (ISASMELT and waste heat boiler; oxygen plant; sulphuric acid plant; electric furnace; materials handling area; services and utilities)

- Development of plant-wide measurement and control standards for the project and upgraded smelter

- Detailed instrumentation design for the ISASMELT plant and waste heat boiler areas

- Electrical design and procurement specification for associated low voltage motor control centre

- Client training in control system configuration and maintenance

Technical highlights:

- Strong focus on simplicity and reliability for maintenance groups

- Transfer of knowledge from multiple technology providers into common control system to provide consistent operations interface

- Fast-tracked project with control system on critical path

Results:

- Reduced project costs through economical project implementation by one group with minimised design group interfaces

- Efficient and cost-effective ongoing control system maintenance due to commonality of equipment and consistency of design

- Minimised project risk

- Cohesive approach to instrument design standards, control system design and configuration

Click here to download the project profile