DLC coating improves the skidding resistance* of the bearing, making the bearing suitable for application to turbo chiller compressors used in high-speed, light-load conditions, and also achieving a higher level of reliability and a lower level of bearing friction loss.

In Japan air conditioning accounts for about 30% of consumer energy consumption (heat source systems) and as such, is responsible for a great deal of power and fuel consumption. As a result, the demand for turbo chillers that are highly energy efficient is increasing. Further, there is a demand for higher levels of reliability in large-scale applications.

NSK introduced angular ball bearings as roller bearings for turbo chillers (compressors) in 2000. Replacing conventional sliding bearings with these angular contact ball bearings resulted in a huge improvement in energy efficiency (energy savings).

In addition, only angular contact bearings with a position-preload were deployed to address the issue of the skidding resistance required for roller bearings used for turbo chiller compressors. Those bearings ended the trend toward multiple bearing configurations, but that approach in turn reached the limit of friction loss reduction.

In response, NSK has added a new member to its lineup for turbo chiller compressors. The new bearing is a DLC-coated cylindrical roller bearing that has greater reliability, less friction loss, and requires less space and resources than the conventional angular contact ball bearing.

- New DLC coating provides improved skidding resistance under severe conditions*

- This new bearing comes with a roller-bearing-dedicated DLC coating that has ample delamination toughness for high-speed operations. Also, it achieves superior durability since its internal design has been optimized to suppress abnormal wear that can cause slipping even in usage conditions that have a pronounced tendency toward slippage and that have poor lubrication conditions as well as high speeds and light loads.

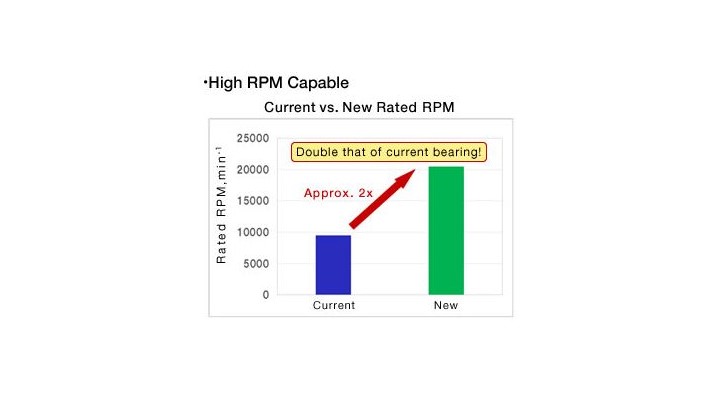

- Furthermore, in revising the internal design of the bearings to reduce friction loss, the rated RPM level of this new bearing is double that of the current bearing, making it well suited for the high speeds of compressors.

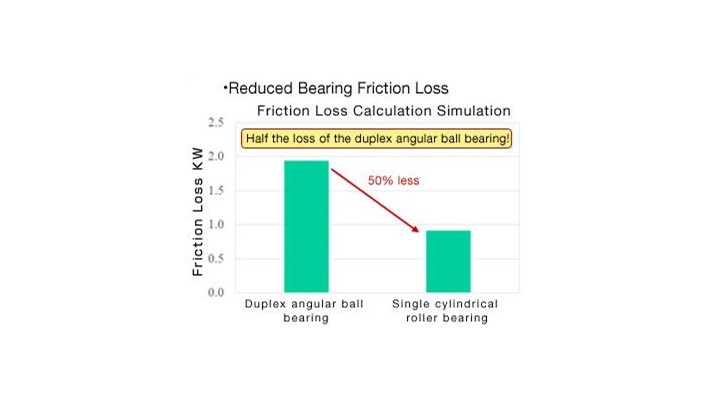

Less bearing friction loss and less space required. In replacing the conventional combination angular contact ball bearing with this new single cylindrical roller bearing, the number of bearing needed is reduced while maintaining a high level of reliability and reducing the space required for the bearing.

Product Benefits

- Less maintenance manpower needed for air conditioners

- Less bearing friction loss for greater energy savings

- More compact design for greater energy savings and less space required

For more information on the new DLC Coated Cylindrical Roller Bearing please call or use IndustrySearch for a direct reply.