All can be suitable, providing the materials used are at least of food-grade standard (AS2070). If the water is to be used for human consumption the tank material must comply with the requirements of potable-water standard (AS/NZS4020).

Steel Water Tanks

The typical Aussie water tanks that we all remember are the galvanised steel water tanks and until recently was the most common material used in the manufacture of rainwater tanks. Galvanised steel is not inherently resistant to corrosion but it is now available with rust resistant coatings such as zincalume or Aquaplate®.

New tanks may leach excess concentrations of zinc which could affect the taste of stored rainwater. These galvanised water tanks may need to be flushed before use.

The most common material used in the manufacture of metal rainwater tanks is galvanised steel. Galvanising is the process of applying zinc to steel. These “galvanised” tanks could be soldered or joined. This join creates what is actually a joint or seam. Solder consists of a combination of lead & tin which is melted with a hot iron and applied to a joint.

Galvanised steel is not inherently resistant to corrosion and must have rust-resistant coatings applied. Initial corrosion of galvanised steel normally leads to production of a thin adherent film that coats the surface of the tank and provides protection against further corrosion. It is important when cleaning such tanks not to disturb this film.

New steel tanks may leach excess concentrations of zinc, which could affect the taste of stored rainwater, but is not a health risk. These tanks may need to be flushed before use.

Aquaplate® (plastic coated steel) has a food-grade polymer skin bonded to a galvanised steel base. The polymer used in plastic coated steel is not resistant to prolonged exposure to sunlight, so tanks must have a top cover in place at all times. Kerosene or similar chemicals typically used as mosquito larvicides can cause degeneration of the polymer coating and should not be used.

The polymer coating must not be damaged when cleaning or installing the tank. If the coating is damaged, it should be repaired immediately using an appropriate sealant to prevent corrosion of the metal portions of the tank.

Steel used in the fabrication of water tanks typically has a stated warranty period of 20years. While the raw material has a 20yr warranty, the manufactured product (the water tank) has a 10yr warranty, on a pro-rata basis. Always read the warranty.

Most steel tank installations require concrete slab, minimum 100mm thick with steel reinforcing, or else you void the warranty.

Stainless steel can also be used to manufacture water tanks. This material does not suffer from the rust or corrosion problems typical of galvanised steel tanks. However, the cost is substantially higher than normal plastic coated steel tanks. The stainless steel tanks still require a seam, where the sheets are joined.

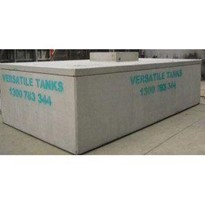

Concrete tanks

Concrete water tanks and ferro-cement water tanks are generally strong and long-lasting. They are very heavy, and difficult to handle. 5000G tank would weigh about 8 tonnes. Concrete water tanks are most often installed underground however smaller tanks are available for above ground.

New concrete water tanks often impart tastes and may leach lime thereby increasing the pH of water. Accordingly these concrete water tanks may need to be flushed before use.

Concrete tanks can either be delivered complete for small or medium sized concrete water tanks, or poured on site for medium and larger concrete water tanks.

Concrete water tanks delivered on site in a complete form are craned off the truck and onto a prepared sand base. These tanks are sometimes in one to three pieces. Concrete sections are sealed primarily with a rubber or synthetic sealing ring or some form of sealant. Sealant is then applied to the inside of the tank at the join to stop the water leaking out.

Cracking and leaking is one of the most common complaints suffered by concrete tanks. As long as the tank can be drained, the cracks can be repaired. In some bad cases, a plastic liner is required, which can be very expensive.

The standard for concrete tanks allows for a certain amount of leakage, while the standard for plastic tanks does not allow any leakage.

Plastic tanks

The most popular type of water tank in Australia is the plastic or poly water tank, typically made with the rotational moulding process. These tanks have been made by some manufacturers using this process for over 20 years. Plastic tanks and plastic liners must be constructed of materials that are at least of food-grade standard (compliant with AS 2070) and if the water is to be used for human consumption the plastic material must actually comply with the requirements of potable-water standard (AS/NZS4020). The rotational moulding industry is one of the few industries that have a comprehensive standard that covers both the raw materials used, and the manufacturing and workmanship of the completed water tanks.

Polyethylene (Poly) is non-corrosive for long life. Polyethylene will not rust or suffer from corrosion as will metal water tanks so time during their service life.

Poly tanks are lightweight and easy to handle - no heavy equipment needed.

Poly tanks are usually made in one single piece. They have no joints or seams where part of the tank has been welded together, and no sealants are used to join any parts of the tank together.

Leading manufacturers such as Bushmans Tanks are manufactured from materials that comply with the light transmission standard (AS/NZS4766) that inhibits the growth of algae. Light transmission is a potential problem that fibreglass tanks have a need to manage.

Polyethylene tanks can be recycled at the end of their service life. Recycled plastic cannot make water tanks because potable water regulations only allow virgin plastics to be used. However, there are many other product applications for recycled plastic. The recycled plastic can have new sun and heat protection added, and go on to enjoy another long life.

Fibreglass

Fibreglass tanks (or GFRP Glass Fibre Reinforced Plastic) are available to store water. These tanks must be manufactured with a food-grade coating on their interior surface. The coating is cured before the tanks are offered for sale.

One advantage of Fibreglass is that it is very stiff or rigid. This means that tank walls can be relatively thin to manage the water pressure. However the disadvantage of this very rigid material is that it can tend to be brittle in nature, being prone to cracking and leaking.

Most Fibreglass tanks have a resin, which is mixed with a catalyst or hardener, along with glass fibres (reinforcement) sprayed onto a mould by an operator. The process is dependent on the skill of the individual. As a result, the process can result in variation from tank to tank.

Fibreglass water tanks allow more light entry than other types of tanks, which encourages algal growth. To prevent this, tanks should be sealed with a black covering inside or painted on the outside. Some tanks are manufactured with sufficient pigment to prevent this problem occurring.

Please visit the Bushmans website for further information.