In its raw, unfinished form, the structure’s most striking features are the continuous 15m tall exterior panels that span from the ground to the full-height of the glassed-in penthouse office space on top.

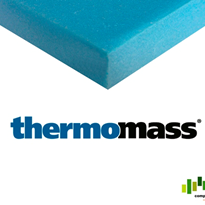

However, these panels are not ordinary precast panels. Each of the 14 separate panels that make up either of the two main exterior walls is insulated with the THERMOMASS Precast Insulation System.

For Alvaro Larosa, the architect on the project, the choice of THERMOMASS was deliberate. With this being his third THERMOMASS building in Cubitt St alone, Alvaro is familiar with the merits of this patented insulation system. Inspired by the works of Tadao Ando, Alvaro seeks to highlight the raw materiality of concrete in his works.

Alvaro’s work reflects Ando’s sentiment of exposing the beauty in simplicity through the clever use of well proportioned space. However, Alvaro also maintains a strong focus on functionality – not just concerning the liveability of a residence, but the ease with which it can be constructed and maintained.

Cringing at the thought of traditional methods of insulating concrete panels – placing insulation against the interior of the concrete shell and then plastering over – Alvaro believes in using insulated concrete sandwich panels that allows the internal thermal mass of the concrete to work in tandem with the insulation to vastly reduce diurnal fluctuations in temperature.

Alvaro’s long-time collaborator, and the project’s builder/owner, Fotios Spiridonos believes in the same philosophy. With the brief of wanting to create a comfortable, inviting space for his future tenants, Fotios readily agreed on the use of the THERMOMASS Insulation System over other insulated precast panel systems.

What sets THERMOMASS apart from the rest is the patented composite connectors that create the bond between the internal and external concrete leaves.

THERMOMASS connectors have been specially developed to have the same thermal expansion coefficient as concrete so as to prevent cracking and spalling common with many other proprietary connector systems.

If you're interested in learning how THERMOMASS can help your latest commercial or residential project achieve a thermally stable environment with significantly reduced running costs, visit our website and learn more.