But yesterday all our troubles really did seem so far away with 25 per cent of national GDP manufactured locally and a quarter of our entire workforce devoted to the task of making stuff.

The long and winding road we have taken since has led right out of the country and taken all but 10 per cent of our manufacturing with it.

Is it time to build a new road? One that leads right out of places like China, the USA and Japan. A road that gives manufacturing clear directions back home? Let's see how the land lies.

The anomalies of scale

It's easy to believe Australia is a major international player because we compete so well on the international stage. Yet Hugh Jackman and a bunch of quite fast Olympic swimmers don't make a large economy.

Quite frankly, we are little more than the chlorine in the international manufacturing pool. Our comparatively small population and distance from major markets have always made it hard to mega-manufacture anything on a large enough scale to compete with the likes of China. And with every economic downturn, every dip in our dollar, and every giddy up in globalisation, our manufacturing base erodes still further.

Made in Australia? Who cares?

Not our younger shoppers it would seem. Having grown up in the international marketplace otherwise known as the Internet, young Australians are more likely to associate product origins with a website than a country. Through buying in cyberspace, the world effectively ceases to exist; geography becomes irrelevant; and website reputation becomes more integral to buyer decision making than such trivialities as patriotism.

It would seem that the very thing that's brought the world market into our lounge rooms has wiped the world off the face of the earth, at least from a marketing perspective. Perhaps www should now stand for World? What World?

Can we break through this web of indifference?

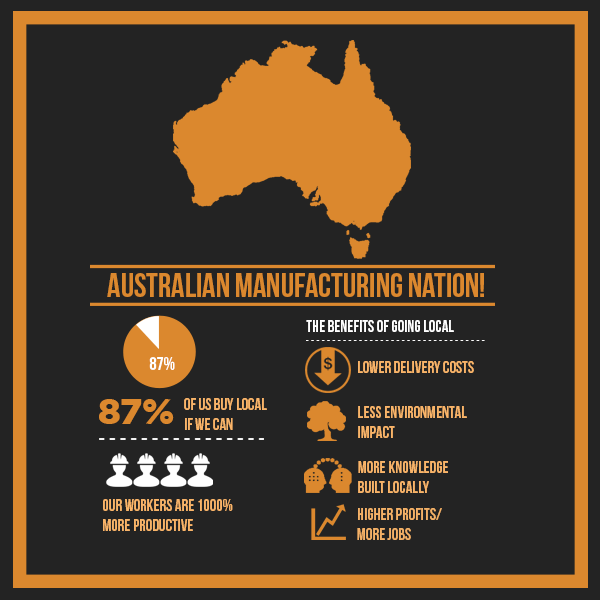

It's not yet a large scale issue; 87 per cent of Australians still buy local products if they can. But as long as eCommerce continues to drive world markets, a new geographically ambivalent generation will continue to grow and that's not good news for Australia's virtual shopping cart.

Long term, local manufacturers must find a way into the minds of this eGeneration. Short term, those same manufacturers must embrace the one thing that can make local manufacture truly viable: automation.

The rise of robots

Studies in the USA have shown that the average American worker is 10 to 12 times more productive than the average Chinese worker. This has nothing to do with work ethic or even relative abilities. It's merely a reflection of better infrastructure and a far greater use of automation and information technology in American manufacturing.

Quite simply, robots can work much faster than people can and it only takes a few people to run a robot. If Australian manufacturers are going to produce on a scale large enough to achieve competitive price points, they have to go global; a market of 20 million simply doesn't offer economies. And these days competing globally is all about speed to market.

Dealing with delivery

The 'I want it now' demands of eCommerce continue to drive manufacturers closer and closer to their markets as they seek next day delivery and even same day delivery to retain customers. Logistically this doesn't bode well for Australian manufacturers operating out of relative isolation in the South Pacific. But it is doable with the right automation in place, a high tech checkout-to-customer strategy and satellite warehousing close to major markets if necessary (and viable).

Building a knowledge base

If manufacturing is over there and development is here, the two are occasional pen pals at best. They will learn little from each other and any meaningful brainstorming involves long haul flights, plenty of them. The tyranny of distance oppresses training and knowledge sharing in a dialogue often already dumbed down by language barriers.

Such scenarios are even worse for start-ups fiddling with prototypes across oceans of miscommunication. The only way to facilitate fast learning and development and gain a competitive edge is to sit manufacturing and development down in the same room (figuratively) so they can get their heads together (literally) all day, every day. And that means bringing manufacturing home.

In conclusion

The future is there for the taking, but we don't have the answers yet. But there are no answers without questions, so let's hear from the real experts: you, the manufacturers and marketers of Australia.

Comment, criticise, discuss and share so all of us can relive some of that 60s magic.

References:

Forbes: Why it's time to bring manufacturing back to the US, 02/02/2015

Sydney Morning Herald: Shoppers happy to buy goods made overseas, 28/072014

The Age: Where to now for Australian manufacturing? 15/04/2014

Roy Morgan Research

-160x160-state_article-rel-cat.png)