The analysed train line starts at St. Gallen central station and leads double-tracked through the city centre. Unexpected squeak in narrow curving that did not occur during the beginning of operation enforced technical measurements.

Application Area

Acoustic analysis of train pass-by during operation

Measurement Task

Mapping of a train with conspicuous curve squealing

Measurement Object

Train of Switzer Appenzeller Train

Measuring Set-up

The scenes were measured with a Star48 and a Ring48 Array depending on what frequencies were of interest and at what distance the measurement has been carried out. The power supply was ensured by the Acoustic Camera mobile power supply which enables to more than 4 hours of measurement. Setting up took 15 minutes from parking at the spot to starting the measurement.

Results

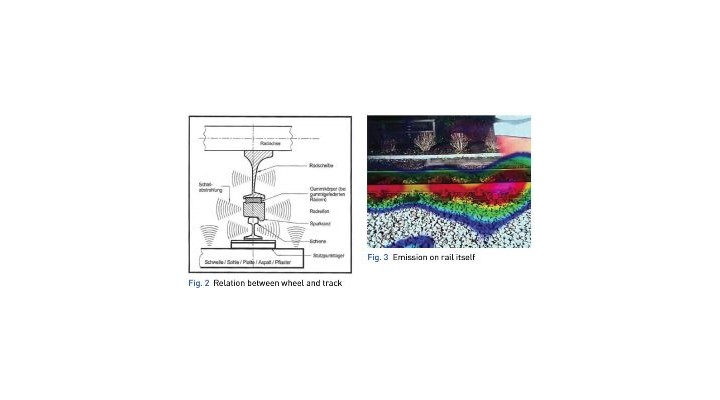

Curve squealing is a highly complex and difficult to describe process. One reason for occurrence is if the rail radius reaches a certain dimension. Here, the tapering wheel tread cannot compensate the different migration distance between the inside and outside wheel only by the rolling motion. The contact of the outside wheel with the rail during riding is responsible for the second noise component. Figure 2 clarifies the correlation.

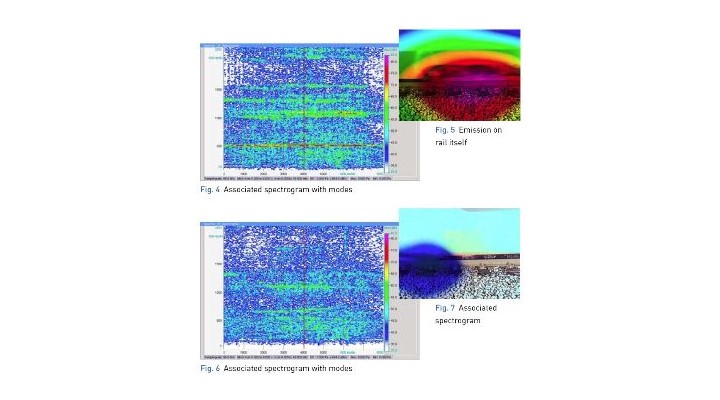

Executed measurements yielded the following results. Emissions of the section of track in front of the vehicle, as seen in Figure 3, imply a distinct radiation of the rail itself. FurtherApplication more, the emission was locally stable within a time limitation which consolidates the assumption. The associated spectrogram (Fig. 4) clearly depicts several modes of the squeal.

For comparison the noise emissions around the drive motors are shown (Fig. 5 and 6). They were locally stable at the vehicle while running the line without any incidence of the squealing. The associated spectrogram (Fig. 7) is considerably less conspicuous. In this case the rail was identified as the noise radiating medium so that corresponding counter-measures could be conducted.

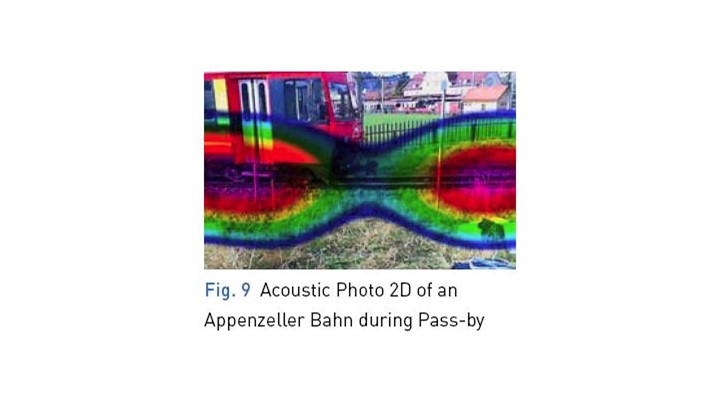

This included the retrofit of a railhead lubrication system on a few vehicles operating at the mentioned line. As an additional effect the reduction of the rail and tread abrasion is assumed. Another measurement should clarify the practicability of the retrofit of wheel noise absorbers for vehicles of the Appenzeller Bahnen on a special line (Fig. 8). For this purpose one train with and another one without a wheel noise absorber was available. In this measurement the rail was identified once again as a considerable radiating surface as seen in Figure 9.

Conclusion

It was of high value for the contracting party of the railway vehicle manufacturer to involve the Acoustic Camera into the examination of the noise emission problem of the wheel - rail system. Introductory examinations revealed interesting results that accelerated the problem solution and confirmed the applicability of the

measurement system for such tasks.

The Acoustic Camera presents, even within economically reasonable funds, the possibility to extend the examinations to practically relevant tribological states such as abrasive rails, bad profiled rails or wheel sets with wheel flats.

To view specifications please click here