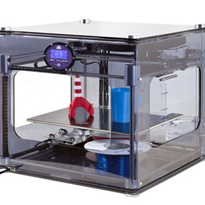

This article explains how FDM (Fused deposition Modelling) and Polyjet technologies can help improve innovation, think faster and branch out to places you thought impossible.

With a range of different technologies this wide and diverse 3D printing can cover a huge range of industries.

"Being the distributor of both Stratasys and Objet Technologies, Objective 3D now have the opportunity to bring 3D printing to the forefront of all industries making this the new industrial revolution," Matt Minio, managing director of Objective 3D, said.

"Any industry wanting to be at the head of the technology game must be involved in 3D printing."

So how have more and more industries adopted and developed 3D printing as the way of the future?

Automotive

FDM Technology is used in the automotive industry for resilient prototypes and parts made from high-performance engineering thermoplastics.

The automotive industry also utilises Polyjet technology. Certain machines such as the Objet Connex 3D Printer has more adaptability than any other 3D printing technology, this is because of the ability to simultaneously print multiple materials at the one time, and even in the same part, making this a key area for automotive design.

Aerospace

3D Printed and patented Fused Deposition Modelling (FDM) is the key to Aerospace Engineers success for prototyping, tooling and part manufacturing.

FDM works with high performance thermoplastics, an "additive" standard which works by laying down material in layers. This technology is used to build jigs, check gauges, fixtures and end-use aircraft parts. Designers in aerospace have also been long-time supporters of FDM concepts for prototyping and modelling.

Architecture

Detailed architectural models can be 3D printed using Polyjet technology, an astonishingly smooth detailed surface ideal for any intricate model. Models can be produced in any array of different materials that when completed are ready for painting. You can build models in a range of colours and also print in a true clear material to simulate glass in your designs.

3D Printing technology has become far more sophisticated in recent times and it is easy to understand why architects are showing so much interest in the technology. Utilising a 3D printer brings forth the realisation that you can instantly visualise not only the design at hand but the entire scope of the surrounding buildings as well.

Commercial and consumer products

The brilliance of 3D printing means that professionals such as industrial and packaging designers, graphic artists, marketing staff and mechanical engineers all understand their products aesthetic and functional appeal with the use of prototypes. Consumer electronics, sporting goods and toys are some of the most popular 3D printed prototypes used today.

Defence

3D Printing in defence is one of the key industries driving 3D printing technology. Tough prototypes that can withstand vigorous functional testing and end use parts that can take chemical exposure and extreme temperatures explains exactly why 3D Printing through FDM technology is becoming one of the most adaptable and widest used technologies on the 3D printing market.

Digital dentistry

Digital dentistry is fast becoming the only way to produce 3D scanned models and a vast range of orthodontic appliances, while the 3D printer does the hard work the dental labs abolish the bottleneck of manual modelling.

3D printing in dentistry is making the accuracy and comfort of patients a much simpler process where dentists are able to produce a complete model of the patients mouth and understand exactly what he/she is about to do before the patient is even sitting in the chair. This means less discomfort for the patient. Matt Minio of Objective 3D believes that digital dentistry through 3D printing is the future and it is here…now.

Education

Education is one of the most important industries that 3D printing has been introduced to. Tomorrows engineers, problem solvers and budding designers require every tool to be able to build a vivid future. 3D printing drives creativity where students get to see and hold their ideas. By bringing 3D printing to the classroom students are exposed to the same revolutionary technology they’ll encounter in their careers.

Researchers have also adopted 3D printing as the new way of life, breaking barriers with the impressive detail, precision and resilience a 3D printer can offer. But that’s not all, through research 3D printing has been able to custom print prosthetics for children with rare disorders, given insights to complex biomechanical questions and has advanced the understanding of human evolution.

Medical

3D printing is empowering healthcare. The medical industry is booming with technological advances which means prototypes for highly accurate surgical guides that imitate the feel and look of the completed medical device are available — fast. These include materials from rigid to flexible, clear to rubberlike.

The medical industry has shown to use both FDM and Polyjet technologies, both of which offer biocompatible materials. The medical industry is now taking advantage of 3D printing to improve patient care and advanced experimental work.

3D printing in outer space

As we are well aware the 3D printing revolution is here on planet earth, now envisage the possibilities when NASA take this 3D printing technology to outer space. You may have heard about plans to support a new initiative to 3D print food for long missions to Mars, yet, have you heard about the plans to bring a 3D printer aboard the international space station.

The introduction of the "Made in Space" 3D printer aboard the ISS in 2014 will be the first ever 3D printer specifically engineered for the zero-gravity conditions of outer space. Could this unlock the potential of off-planet manufacturing and transform the future of space exploitation? The concept of 3D printing in outer space is just another notion that simply makes sense.

So what does the future hold?

3D Printing is going to revolutionise the way things are made in all industries.

Will we one day be able to build large, more complex designs such as bikes or cars? Will every home have a 3D printer? How will 3D printing change the world as we know it? Objective 3D together with Stratasys the world leaders in 3D printing technology are excited to be a part of this.

"The team at Objective 3D have extensive experience in both FDM and Polyjet technologies and are ideally positioned to help businesses filter through the range of technology options," Minio said.

"With two decades of hands on experience in 3D printing, Objective 3D can tailor a solution suitable for your business. It is no doubt that that any idea can become a reality."