The Challenge

Australia Post used ball transfer tables for manual sorting of bulky international mailbags weighing up to 35 kg. This required substantial and repetitive manual effort by operators to push, pull and rotate the bags, exposing them to potential musculoskeletal injury. To address this issue Australia Post looked for alternative solutions that would substantially reduce operator input and exposure to risk of injury. With a targeted push/pull force of 50N (5kg) for a 35Kg bag, it was acknowledged that this target would in all likelihood require a powered solution, adding to operating and maintenance costs.

The Rotacaster Solution

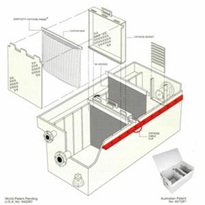

Rotacaster proposed a manual transfer solution utilizing their 48mm Rotacasters combined with polyacetal (POM) spacer rollers. The roller’s smaller diameter was designed to provide support for the soft packaging, while minimizing friction and reducing the number of Rotacaster wheels required. Australia Post and Rotacaster collaborated on the design and construction of the transfer table. Trials were successfully undertaken at an Australia Post gateway

Outcome

The solution resulted in a significant reduction of push/pull forces to between 40 and 70N (4-7kg) in all directions on the table. Australia Post considered this a remarkable achievement in the absence of any powered assist

Additional Advantages

In addition to reducing the push/pull forces required, without the cost noise and maintenance associated with a powered solution, the polymer surfaces of the Rotacasters and spacer rollers have demonstrated a lower affinity to adhesion of labels and stickers from packages, further reducing down time and maintenance costs.