The Parameters

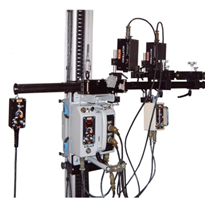

- KAT – All position carriage, used in 1G, 2G, and 3G positions

- MOGGY- Trackless carriage: Standard and Dual Torch models

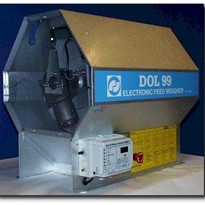

for continuous and stitch welds - KBM – 18 and 28 models for offsite steel suppliers, hand held model for out of position bevels

The Project

Recently commenced is a project that will see Gullco welding automation used to produce two UK Navy Air Craft carriers in the coming months. This shipyard in Cammell Laird, Merseyside has selected Gullco equipment after a list of companies where tested for their effectiveness to meet military welding inspection standards.

It was agreed upon by the UK Shipyards that the automation equipment supplied by Gullco was the most reliable and most consistently met weld quality standards.

It is important that the automation produce high integrity welds at an increased frequency to previous production methods in order to increase manufacturing efficiency.

This project will see various types of welding applications throughout its completion and the welding technicians will utilize the versatility of the KAT all position carriage to produce the majority of these welding procedures.

The Challenge

The shipyard in Merseyside was faced with the task of producing 2 aircraft carriers under strict deadlines, with increasing quality standards. These issues are then compounded with having to source, and train welding technicians on the selected automation equipment which will be used to complete the project.

Early on in this process it became apparent that finding reliable, easy to use weld automation equipment, which is coupled with great onsite training and back end support, would be the critical challenge to the successful completion of this high profile project.

This was combined with the challenge of having high integrity bevels, with consistent root face made off site by a 3rd party company who would produce the steel for the completion of the carriers.

The Solution

After several companies made proposals, the GULLCO International line of welding automation equipment was selected - which was in part due to its versatility.

Through the use of a track and mounting device system the KAT carriage is able to operate in all positions, reducing the amount of equipment training necessary to complete a variety of weld applications. This was especially appealing when combined with onsite training provided by Gullco’s welding technicians.

Another key factor to this solution was Gullco’s great back end support team for both technical questions and equipment, giving them the peace of mind to put the automation to the test.

The solution to the steel problem would be solved with a gift. The shipyard would purchase two KBM beveling machines from Gullco, which could produce the consistency necessary while eliminating material distortion and give them to the steel manufacturing facility in order to insure quality standards and regulations were met.

Other equipment involved in this solution were, Moggy trackless friction drive carriages, used to produce the welds in the flat position, and a hand held beveling system for out of position beveling done during manufacturing.

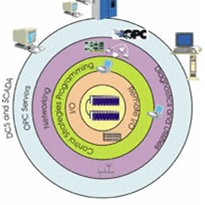

The extensive line of GULLCO automation equipment allowed the shipyard to source all of it products from one company streamlining the process which would carry over into efficient training sessions.

It was also of benefit to know that support for the equipment could come from the one source and cover the range of equipment.