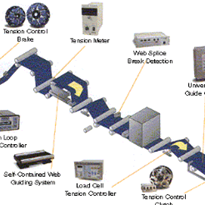

With current drive solutions, sensor technology, bus systems and amplifiers tension control has become state of the art in converting lines, metal, paper and wire manufacturing and processing.

Nowadays, tension measuring load cells are part of the standard equipment in running web production lines.

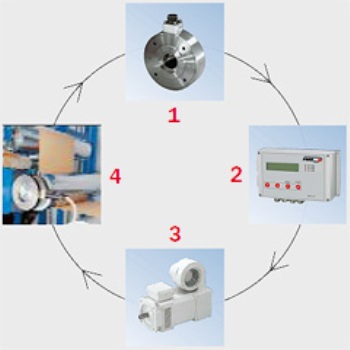

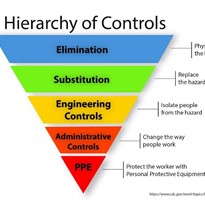

Closed loop tension control principle

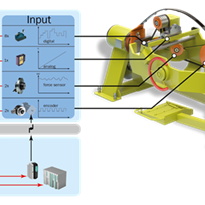

- Force sensors measure the effective material tension

- The tension controller amplifies the measured signal from the force sensor and calculates an output value from the difference between the reference and feedback values

- The drive, brake, or clutch converts the output value from the tension controller into a corresponding torque or speed

- Constant tension in the process material can be maintained

Advantages

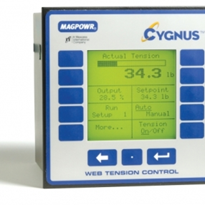

- Defined, adjustable material tension

- Reproducible values in physical units (Newtons, Pounds, etc)

- Known manufacturing conditions for finished products (quality recording capability)