The $170,000 facility, acquired as part of the Charles Darwin University North Australian Centre for Oil and Gas (NACOG), will enable industry to perform material tests locally, which were previously only available interstate.

Associate Professor Krishnan Kannoorpatti said the new facility would enable oil and gas and mining industries to better select suitable materials and fabrication methods to suit Territory conditions.

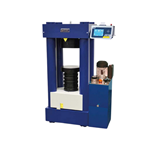

"The facility tests the static and dynamic properties of materials," Kannoorpatti said.

"This type of testing will allow industry to test the strength of welds and conduct failure analysis, which in the future could prevent catastrophic failures.

"The facility will not only assist industry to test materials' load-bearing ability, but also ensure their welding procedures are of the required standard for oil and gas processing."

Kannoorpatti said many of the structures used in oil and gas processing would be located offshore, so it was vital that both mechanical and corrosive properties of materials could be tested according to local conditions.

"Some of the vital research being conducted at NACOG will focus on corrosion-related damage, which costs the industry between 3 and 5 per cent of GDP, equating to trillions of dollars each year world-wide," Kannoorpatti said.

"Microbiologically influenced corrosion (MIC) is a problem in structures that are immersed in sea waters. Welding is the main fabrication method used in most industrial structures," he said.

"Previous research suggests that welds may be more prone to MIC than the base metal. We will test the weldments being used extensively in the infrastructure and the oil and gas industry.

"The new facility will also allow us to conduct research which tests the interaction of stress and corrosion properties of materials under various conditions."

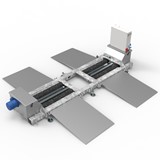

The new Instron 8802 has a load capacity of +or – 250kN or in static up to 312kN. It is a modern servo-hydraulic testing machine completely controlled using a computer.

The facility is jointly funded by ConocoPhillips, ENI, INPEX, Total and other participants in the Ichthys LNG Project Joint Venture and the Northern Territory Government.

The facility opens to industry in July.