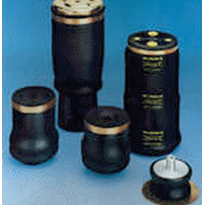

Air Springs Supply has more than 30 years' experience as a leading Australian supplier of Firestone air springs and associated pneumatic technology for the transport sector, including heavy duty Firestone Airride rolling sleeve and convoluted airbags and Ride-Rite and Coil- Rite supplementary air suspension kits for lighter trucks, utes, vans and 4WDs.

"Substitute airbags can be closely modelled on the appearance of Firestone original, but many have problems associated with poorer quality design, engineering and construction," Russell Chown, Air Springs Supply sales manager, said.

"This can adversely affect reliability, serviceability and risk management, which are crucial to transport operators.

"Sensible operators wouldn't think of putting their costly vehicles on inferior look-alike tyres — that would be appalling risk management — so why would they fit suspension look-alike products?

"A vehicle's suspension is every bit as important to reliability, safety and risk management across major industries using trucks, including automotive and transport, mining and resources, manufacturing and logistics, fleet management and safety."

Telltale defects of look-alike springs of which transport operators should be aware include:

Rust resistance

The Firestone Air spring (Figure 1), left, with trivalent chromium coating, has been subjected to 200-hour salt spray testing, more than twice the normal 96 hours. The rusty airbag, right, failed after the standard 96 hour test.

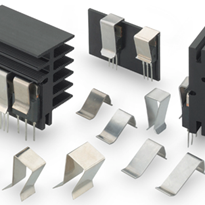

Sealing reliability

The stud braze technique used on Firestone Air Springs provides a continuous seal (Figure 2: pictures one and two, left) while non-genuine parts may show irregular welds and potential leak points (Figure 2: pictures three and four, right). The brazed fitting create a more reliable seal, while the welded fittings shown create a weak spots which can affect the integrity of the seal around the fitting joint, causing leaks.

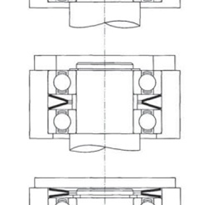

Firestone's highly engineered rib design (Figure 3: left) provides a robust piston while an inferior piston design (Figure 3: right) may lead to premature failure. Firestone performs extensive load testing to ensure piston durability before its products are fitted to trucks.

Piston stud strength

Firestone air spring piston stud, left, is designed for strong axial support, with a solid one-piece design giving optimal axial and lateral strength. A lower quality design (Figure 4: right) gives less support and presents a greater possibility of bending. The two-piece welded design has less axial rigidity and could break off after extended use.

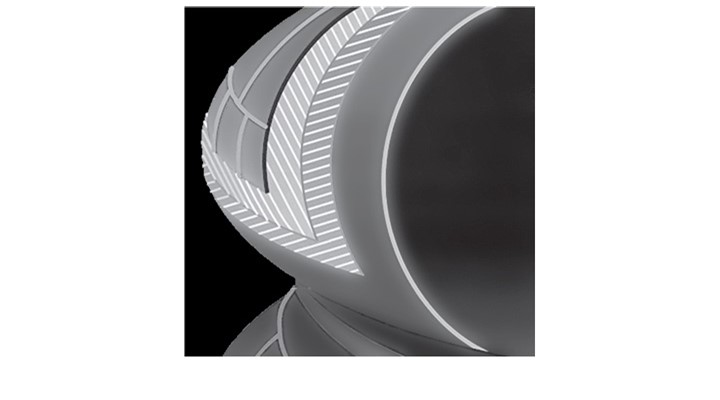

Firestone's distinctive fabric cord is not something the naked eye can readily detect, but does make a difference in air springs performance. The graphic (Figure 5) below shows the strongly engineered inner layer, first ply, second ply and outer cover.

"Firestone's proprietary rubber compound utilises the highest grade materials and the best compounding technology in the industry," Chown said.

"Firestone air springs meet and exceed the world's most rigorous testing standards. They don't leave the factory without first passing 190psi (13 bar) proof testing."

When it comes down to it, trucks are a major livelihood for many and vital to a huge range of businesses, so keeping your truck running and on the road is crucial.

"Truck manufacturers know and trust Airride as OEM and Firestone is constantly working to set the quality bar higher," Chown said, adding that Firestone is the only air spring manufacturer in the world with manufacturing facilities in the US.

Air Springs Supply recently enhanced its commitment to national and global standards of quality assurance by gaining ISO 9001: 2008 Quality Management Systems – Requirements certification.

The company places a high priority on continuously reinforcing its customers' confidence in doing business with an organisation that can consistently meet or exceed their needs on time.

ISO 9001 certification is invaluable to customers in demonstrating that the organisation involved can consistently provide products or services that meet the requirements of customers and of any applicable regulations relating to them.

ISO 9001 benefits to customers include assurance of global standards of consistency, quality and supply of products for which Air springs is exclusive national distributor, including Firestone air springs.