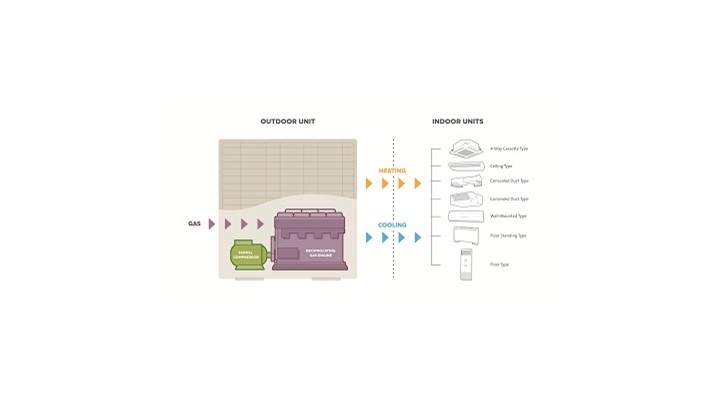

The pioneering feature of Yanmar's variable refrigerant flow (VRF) air-conditioning system is the gas powered engine, which provides improved energy efficiency and more options for buildings where electricity supply is constrained, compared to the equivalent electric condenser.

Gas powered air-conditioning (GPAC) systems tackle site power supply issues and avoid power upgrade costs while lowering carbon emissions.1

About Yanmar

Origin is the sole Australian distributor for Yanmar gas powered VRF air-conditioning systems.

As one of the first companies to manufacture gas-driven systems, Yanmar has remained Japan's market leader for 25 years and has more than 250,000 systems installed worldwide, with approximately 300 systems in Australia.

Benefits of installing gas powered air-conditioning systems include:

Superior performance:

- Gas powered air-conditioners use up to 90 per cent less electricity than the equivalent electric condenser.

Cost efficiency:

- Up to 50 per cent energy cost savings on the condenser compared with the equivalent electric condenser.2

- There are ongoing energy cost savings due to the condenser using natural gas rather than electricity.

Environmental credentials:

- Using gas rather than electricity to drive the compressor can reduce condenser-related greenhouse gas emissions by up to 50 per cent.2

- It may also help to reach sustainability targets and improve a building's Green Star and/or NABERS ratings.1

Avoids power upgrade costs:

- GPAC may lower customers' total capital outlay where power upgrades are avoided.

Lower electrical load

- GPAC systems do not require three-phase power. A Yanmar 85kW condenser has a running current of only eight amps, single phase.

Efficient performance

- While the cooling performance of the gas model is comparable to an equivalent-sized electric model, it offers superior heating performance in colder temperatures by using exhaust heat from the engine to reduce the de-icing cycles often needed with electric models.

- There is no loss in heating performance down to -10ºC.

- Low noise, compared with the equivalent electric system.

Low electricity demand

- Reduced peak demand can mean considerably less electrical infrastructure required and lower peak demand charges.

Building owners have the opportunity to improve NABERS (National Australian Built Environmental Rating System) and/or Green Star environmental ratings when implementing a GPAC system.

Higher NABERS ratings have been linked to better rental returns* for commercial properties, while also contributing to capital value.

Origin's specialist technicians work with engineers, consultants, architects and system installers to deliver GPAC installations in commercial and industrial properties Australia wide.

Typical installations include:

- Apartment complexes

- Education facilities such as schools, universities and TAFEs

- Aged care facilities and hospitals

- Hospitality sites

- Office and retail sites

- Clubs

- Councils

- Warehouses

- Community centres

- Residential properties

There is a flexible range of Yanmar's GPAC systems available

Sizes range from 14kW to 85kW condensers, with some models available in three-pipe heat recovery configuration.

The systems are multi-split, reverse-cycle, inverter-style, air-cooled systems with gas heat pump condensers.

Either natural gas or LPG can be used and both natural gas and LPG models are available.

A 14kW system may be suitable for a large residential house, while a commercial site of up to 15 stories may require multiple larger systems.

New energy efficiencies make old office environmentally friendly

FMSA recently completed an environmental retrofit of its office building in North Melbourne, which included installation of 3x85kW Yanmar gas powered air-conditioning systems. This helped to reduce FMSA's energy usage and energy costs while improving the efficiency of its building.

FMSA is a Melbourne-based firm offering architectural and construction management services. Its building has three office floors, each approximately 400 square metres.

FMSA worked with Greater Pacific Engineering on a design-and-construct basis. The project incorporated several energy saving initiatives, such as an environmentally efficient building management system (BMS), in addition to the Yanmar gas powered air-conditioning system.

The BMS shuts down the air-conditioning system when the windows are open. FMSA completed this project with the assistance of the Green Building Fund.

"The choice of the gas-fired system meant a 50 per cent reduction in greenhouse gas emissions ... while also creating a counter-cyclical effect on peak demand," Michael Fooks, FMSA Director, said.

This means FMSA now saves on energy usage and costs and has added to the quality and efficiency of its building in the long term. Fooks said the primary reasons for implementing gas powered air-conditioning were sustainability factors and improving energy efficiency.

"It is worth giving serious consideration to gas-fired climate control, as opposed to more conventional electric systems."

Addressing power constraint issues at the University of NSW

The University of NSW (UNSW) installed 20 GPAC systems throughout its Kensington campus. The site is approximately 38 hectares.

The university engineer, Ray Filetti, explained that site power problems experienced by UNSW were the main motivation for the upgrade.

"The system delivered all the benefits promised and we were so impressed that we went on to purchase close to a dozen additional units, purely based on the practical benefits they deliver," Filetti said.

The lower energy costs associated with the gas units also contributed to the decision to install GPAC systems.

"We have saved on electricity costs and have avoided upgrading our electricity supply, which would have been a necessary and expensive exercise if we had gone with electric units instead … knowing that we are doing our bit for the environment by lowering our CO2 emissions is a nice bonus too."

UNSW have found the systems to be reliable in hot and cold temperatures.

"We have found the systems to be of excellent quality, they are a highly developed piece of equipment. Based on our positive experience with the gas powered air-conditioning units, we are very comfortable recommending them to other organisations needing to upgrade their reverse cycle air-conditioning systems."

1 Statements are made in comparison with an equivalent electric condenser and are dependent on unit size and location.

2 Figures are approximates when compared with an equivalent electric condenser and vary depending on unit size and location.

* Building Better Returns, A Study of the Financial Performance of Green Office Buildings in Australia, Research by the University of Western Sydney Australia and the University of Maastricht Netherlands in conjunction with Jones Lang LaSalle and CBRE, 2011.