SUSTAINABLE AND ECONOMIC TECHNOLOGY: PRECISION CLEANING

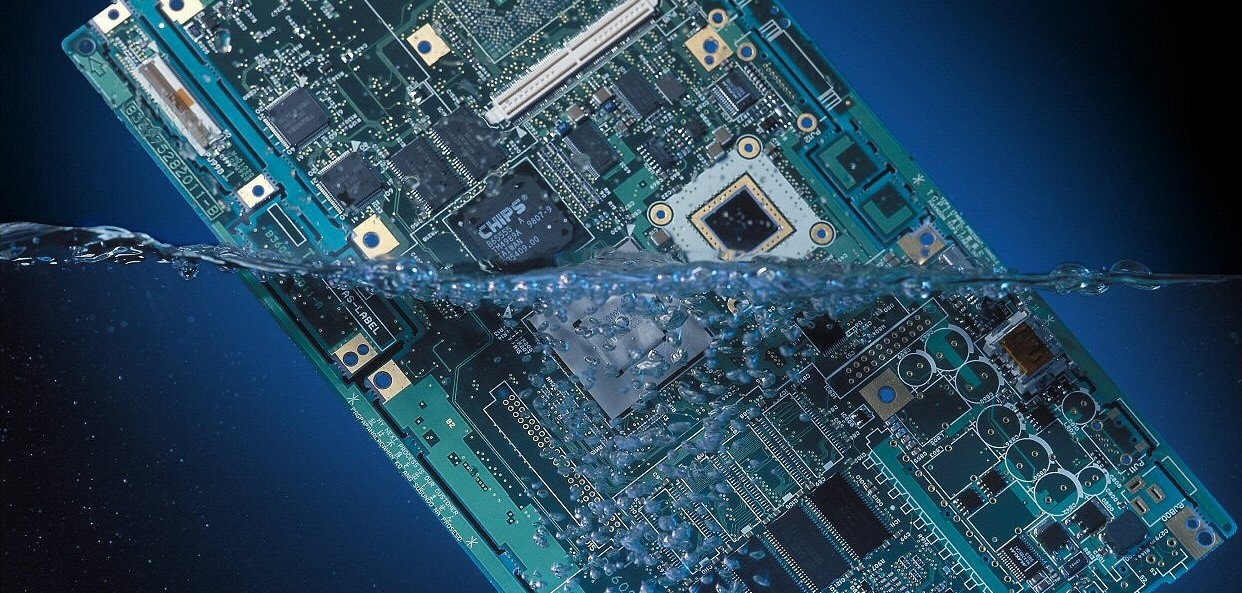

Precision cleaning means a surface treatment process in order to remove contaminants from a surface at a micro-level. For high-tech industries such as aerospace, medical, pharmaceutical, or electronics stringent cleaning requirements apply.

Failure to remove contamination at the micro-level might have significant effects on product reliability and performance. Therefore consideration of below parameters plays a vital role in the selection process of appropriate process, material, and equipment:

Solvent vs Aqueous Cleaners

In nature salts and oxides are soluble only in water whereas oils and greases are only soluble in hydrocarbons and solvents in other words “like dissolves like”. Because of this reason, solvents have a much broader process window even though water could work with adding a detergent.

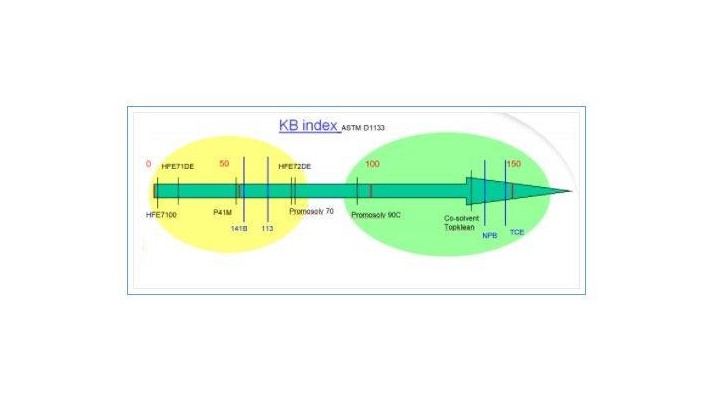

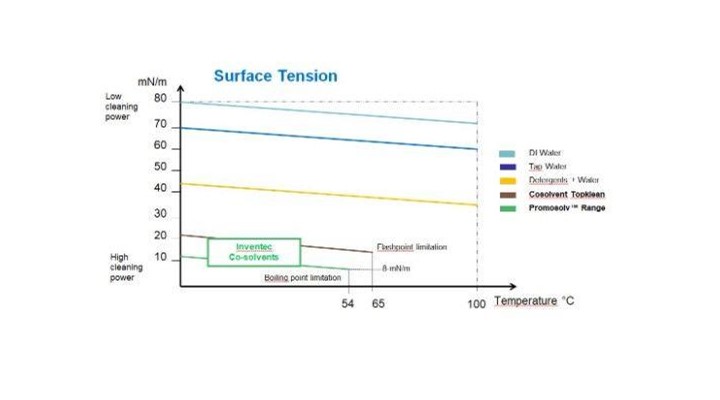

Solvents are also having much less surface tension and lower surface tension always means higher cleaning power. Lower surface tension means higher wetting power which allows solvents for deep cleaning in micro areas such as blind holes or under surface mounted components.

Internationally standardized solvency power is measured as Kauri Butanol (KB) value which is determined by ASTM D1133. A higher KB value means higher solvency power but in some cases, it also means toxicity and ozone depletion. For example, the U.S. Environmental Protection Agency (EPA) has proposed banning TCE in vapor degreasing and has targeted nPB as one of its top 10 chemicals to undergo risk evaluation to determine if it presents an unreasonable risk to humans. The European Union has already banned TCE in vapor degreasing and nPB is scheduled for 2020.