A new technique developed by Echuca-based Foodmach makes it possible to maintain their line speed at up to 100 packs per minute with the 'instant' adaptability of robots. As a welcome side benefit, the new system could be retro-fitted, allowing SABC to keep much of their existing equipment, saving significant time and money during installation.

SABC's Operations Development Manager John Kearvell explained, "Our range includes traditional beers and premium ready-to-drink brands, all palletised on the same machine. We wanted a system with almost infinite flexibility to deal with whatever pack size our marketing people might dream up."

He contacted Foodmach who could offer both traditional and robotic palletising solutions. "In the engineering sense we realised it just had to work, even though we were probably the first bottlers on earth to try it. However the cost of failure would have been enormous because all our product goes through that palletiser."

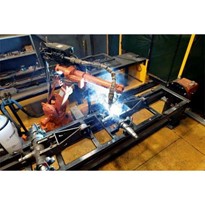

Foodmach took the initiative of building, programming and proving a prototype at their Echuca plant earlier this year. At Foodmach, Product Development Director Peter Marks recalls, "The big challenge was creating a way to break through the speed limits of robots used for palletising. Thanks to our history in high volume palletising, our team was able to put together the best of established and robotic technologies for a 5 fold increase in speed."

Now known as Robomatrix, the palletising system has been operating at SABC since July 2003 now with the only noteworthy teething problem being a need for special alloy gripper heads. At up to 100 cycles per minute, the original stainless steel heads soon succumbed to metal fatigue.

Kearvell concluded, "Traditional line dividers and pack turner systems were very limited in the range of packs they could handle. Compared to the old ways, the Foodmach Robomatrix system is hugely cheaper and infinitely more versatile than any other option we could think of."

Following the success at SABC, Foodmach have already secured an order for a Robomatrix retrofit to an imported high speed palletiser, at a major food producer. "In simple terms," commented Peter Marks, "the overseas suppliers just couldn't meet the flexibility this client required, and Robomatrix will deliver all they want both now and for the foreseeable future in their packaging developments."