What is a Disc pump?

- Highly innovative design, operation with boundary layer and viscious drag forces.

- Parallel disc pump mechanism, Discpac- delivers laminar, pulsation-free flow.

- Minimal contact between pump and pumpage – leads to low pump wear and no product damage.

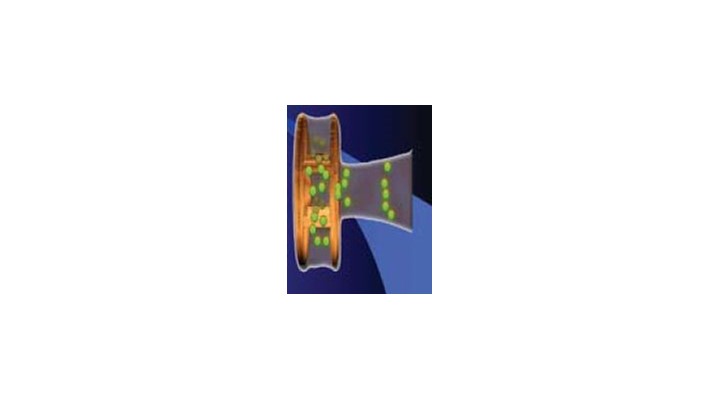

Discpac pumping system:

Discpac – series of parallel rotating discs - creates a boundary layer. Energy transferred to successive layers of fluid by viscous drag.

Designed for hard to pump applications

Old pump technology

‘Impingement’ pump mechanism, eg. Impeller, vane, lobe, screw etc, leads to:

- Pump wears out quickly.

- High spare parts costs

- Inefficient for viscous products

- Frequent failure in high-solids or air-entrained fluid applications.

- Damage to shear/delicate products.

Disc pump advantages 1

- Laminar flow = Low NPSHr

- No close tolerances = able to pass high solids

- Clog resistant = High uptime

- Non-impingement pumping = Longer pump life

- No damage to delicate products = Higher yields

Disc pump advantages 2

- Pulsation-free = Reduces wear on pump and surrounding pipework

- Able to run bone dry, deadhead discharge and starve suction.

- No radial loads = Longer pump life

- Same operating range and models as PC and centrifugal type pumps.

Hard to pump applications

- Highly viscous fluids

- Slurries with high solids content

- Severely abrasive fluids

- Fluids with high volumes of entrained air

- Delicate / shear sensitive products

- Fluids containing large and / or stringy solids

Pump models

- Horizontal

- ANSI models

- Sanitary

- Direct-coupled

- Close-coupled

- Frame-mounted

- Submersible

- Vertical sump

- Dry Pit

- Cantilever

- Over-Under

- API=610

- Self-priming

- Sump

Disc pumps are an engineered product.

Pump operating range

- Flow rates range from 2-10,000 GPM

- Discharge pressures up to 1000ft in Discflo standard pump line

- Pumps can be configured for an application by varying the size, number and spacing of discs in the discpac.

Summary:

- Disc pumps have demonstrated significant cost savings, up to 90% by:

- Reducing spare parts, maintenance, downtime and pump failure

- Increasing pump life and where applicable, product yield and quality

Compared to its competitors in all hard to pump applications.

-205x205.jpg)