As most managers would be aware calibration of equipment is paramount to producing quality products. In this case with robotic welding even the smallest of errors can result in dire consequences for your product and your business.

This is where Sigmund comes in.

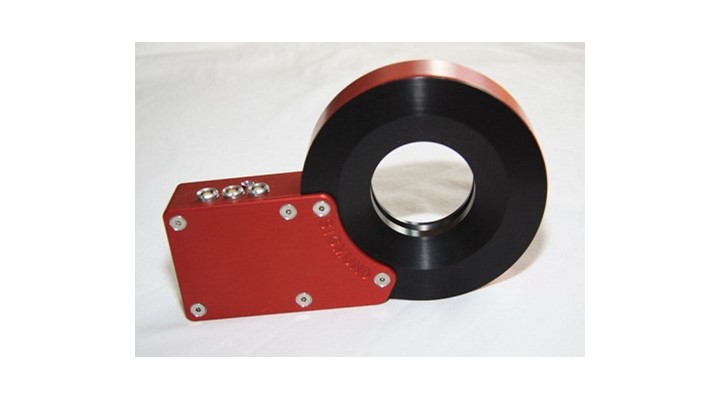

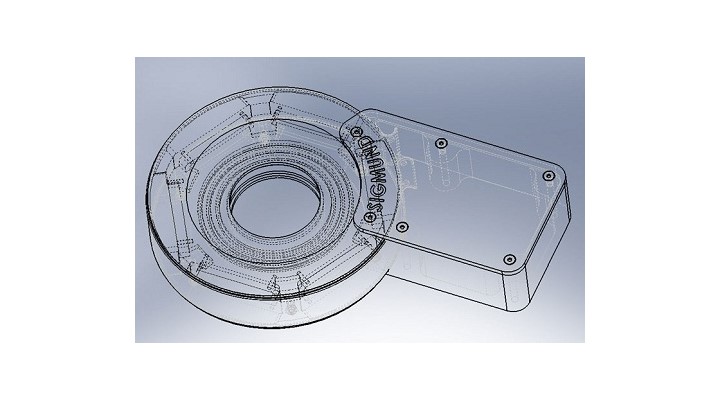

Sigmund has been developed in England to provide the measurements you need to improve your welding processes without having an impact on cycle time.

It is a precision optical device which calculates the position of the torch and the diameter of the wire by firing over 30,000 light beams across its field of measurement.

By choosing positions on the tool to take cross-sections, information about the position, contamination and wear and tear can also be acquired.

Sigmund is the fastest device of its kind to measure and analyse relevant variables in real time. Each measurement takes less than a second. It will improve your process stability, traceabillity and strengthen your quality systems.

The benefits of using Sigmund are:

- Improved quality, stops before a substandard part or product is produced.

- Reduced rework, corrects the tool automatically or generates an alarm on tool deviation.

- Improved process stability, ensures reliable torch position.

- Enhanced traceability and management reporting, logs measurement along with product id and time of manufacture

- Easily connects to you existing network

- No cycle time impact, measures in less than a second during product transfer time.

Sigmund is now exclusively available through Welding Automation.