Disagreement typically arises between mine production, the beneficiation plant, the port facility, the shipper, and even the buyer. Too often, the tonnages just don’t add up. As is often the case, moisture is a contributing factor.

Not surprisingly, mining companies worldwide are increasingly utilizing online moisture monitors to calculate dry tonnage along the value adding chain from pit to port.

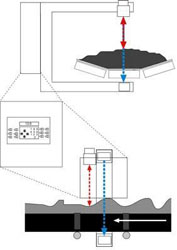

Significant advancement in the last 5 years in online moisture monitoring technology is seeing online moisture analysis becoming the norm rather than the acceptation. In particular, the use of the moistscan microwave technique has proven its reliability time and again on a diverse range of mining and mineral processing applications. The moistscan microwave technique measures changes in the strength and speed of the microwave signal caused by the presence of moisture in the material being analysed. Two antennas, one below the conveyor belt to transmit the signal and one above the material on the conveyor belt to receive the signal are integrated into a c-frame which is attached to the conveyor. A microwave signal of a frequency optimized for the material being analysed, is generated by specialist technology housed in an electrical control cabinet also attached to the c-frame. An ultra-sonic sensor is attached to the upper arm of the c-frame to record the depth of material upon the conveyor. By continuously recording the microwave signals stenght and speed and the depth of the material on the belt the percentage moisture is accurately calculated.

Examples of mines who have integrated online microwave moisture analysers into their operations include Xstrata’s Newlands Coal Mine, BMA’s COMET Coal Project, Codelco’s Andina Copper Mine in Chile and Imerys Kaolin Mine in Brazil.

Newlands is using online moisture anlaysers installed at key points along the supply chain. Prior to using online moisture analysers Newlands relied on sampling to estimate the amount of moisture in coal entering and exiting the wash plant. A more accurate way of measuring moisture which did not rely on sampling was needed. A Moistscan® MA-500 is installed to measure the moisture content of coal from the underground mine. Each shift moisture data is used in conjunction with weightometer readings to accurately calculate the dry tonnage mined. Another Moistscan® MA500 is installed on the product belt to monitor the moisture content of coal exiting the wash plant prior to shipment by train to Abbot Point Coal Terminal. As an added benefit the unit is linked to the control room enabling plant operators to view instantaneous and average moisture readings in real time thus enabling early detection of potential problems with dewatering.

“We’ve installed the MA-500 on the trunk belt coming out of underground to adjust tonnages for moisture and know exactly how much we mine. This is reconciled with what is delivered to the ROM Bin”. Technical Services Superintendent.

BMA has purchased 8 online moisture analysers to reconcile tonnages at various points along the value adding chain. Three units are installed on ROM coal, 2 units are located within the washplant, 1 is located on the train loadout and 2 are located on reject belts.

Codelco’s Andina Copper Mine in Chile recently purchased moisture anlaysers to calculate dry tonnage feed to their SAG Mills. The dry tonnage feed as determined by the MoistScan® units is now a key performance indicator for the Andina operation.

Imery’s Kaolin Mine in Brazil recently purchased 5 MoistScan® online microwave moisture analysers which will be installed at various locations to calculate net dry tonnage production throughout their operation.

Contact [email protected]