A leading Dairy producer is known for its quality, primarily for its dairy products, but also for its packaging. So when designing a new single serve, brick pack conveyor line, they insisted on zero risk concerning product damage. The damage they feared most was losing the straw.

Existing wedge conveyors clamp the pack from the sides when picking them up from the line. This involves a bend action from horizontal to vertical movement and backwards, a relative movement that can rub the straw off the packet, an unacceptable concession to quality.

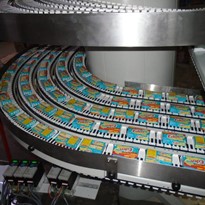

However, using the AmbaFlex Spiral Conveyor from the SVs series does not involve such risks. First of all, the product can stand stably by itself on the unique “flat-top” belt and is not clamped at all. And secondly, the endless, highly polished stainless blade guides have no seams that could also damage the pack and the straw.

AmbaFlex was already the customer’s logical choice as they are the only alternative for a full stainless steel spiral conveyor. There are no hidden soft metals like Aluminum or similar that can corrode when cleaned with the usual diary industry detergents. The complete frame and belt guides are made out of seamless welded stainless steel. Furthermore, the bearings and shafts are stainless steel and bolts are avoided where-ever possible to increase the cleanability.

Finally, AmbaFlex is the only supplier that has managed to design a stainless steel base chain that is strong enough for use in spiral conveyors, a crucial component when everything has to be in stainless steel.

One more proof of AmbaFlex’s leading position in Spiral Conveyor Solutions!