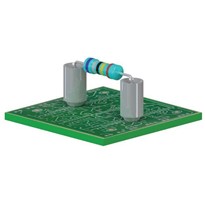

Electrical Ceramic Insulators / Alumina Insulating Ceramics are used in applications that require a non-conductive rigid component and/or source for heat dissipation. Although all ceramic formulations can be used in electrical applications, Steatite and Alumina (all grades) are the most common choice due to their excellent electrical properties. Electrical insulators commonly have coatings applied including glazing, teflon coating and metalizing. Metalization of ceramic electrical insulators is common practice for ease of installation into control panels and electrical boards through soldering.

Electrical Ceramic Insulators / Alumina Insulating Ceramics are most often used to provide non-conductive bridges between electronic components, however, they are also installed into control boards and boxes as a heat sink.

What are Metallized Ceramics?

Metalized ceramics can be used for a number of things, the primary being the bonding of the ceramic to metal components by soldering or brazing. The resulting assembly is more permanent than mechanical assemblies and can be used in areas in which mechanical assembly is not practical or desirable. It is often used in vacuum and panel feedthrough applications.

Metalization is a thin coating of a metal material on the ceramic which provides an interface between the ceramic and the solder or brazing material used to bond to a metal component. Unmetalized sections of the part can also be glazed or Teflon coated.

Alumina and steatite are the materials that we make that are used in this process. Size capabilities and consistent with the sizes for unmetalized components of the same material.

Overview of Main Physical Properties:

- Good electrical insulation

- High mechanical strength

- Excellent wear resistance

- Excellent corrosion resistance

- Low dielectric constant

Overview of Main Applications:

- Seals and other components

- High power electronic or electrical insulation

- Wear resistant inserts

- Insulating washers or bushings

- Semiconductor components

- Automotive sensors

- Frictionless clutches

Ceramic Oxide Fabricators can custom make ceramic components to suit your application.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.jpg)

-160x160-state_article-rel-cat.png)