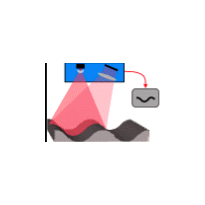

The laser profile scanners operate based on the principle of laser line triangulation, detecting two-dimensional profiles of target objects. The laser profile scanners can be operated in a stationary mode where bead and groove measurements are taking place. This is done by installing the scanner on a fixed unit looking at the moving objects. It is also possible to generate a three-dimensional profile by means of traversing sensors or measuring moving objects. 3D laser scanners measure fine details and capture free-form shapes to quickly generate highly accurate point clouds.

The technology provides the user with accurate measurements and the ability to fully utilize, visualize and modify data with CAD. This non-contact measuring technology converts a physical model into digital 3D Computer-Aided Design (CAD) with the help of scanning software. It is becoming an essential tool for producers who need an accurate dimensional inspection, virtual image, analysis, and even physical prototype manufacturing.

It allows for careful preparation of production systems involving machinery placement, facilities, repair, and human ergonomic interplay. Laser Scanner is a vital performance measure to ensure the initial vision has been realized as intended.

Bestech Australia supplies laser profile scanners from Micro-Epsilon which are amongst the highest performing non-contact sensor technology for detection of 2D/3D profile due to its superior accuracy and fast measuring rate. It can be easily integrated into the existing process via the available SDKs or the GigE Vision standard. Processed values can be directly transferred to the control system via Analog and Digital interfaces.

Bestech Australia supplies Laser scanners in the scanCONTROL range, with a red laser diode or with the patented Blue Laser Technology. Laser scanners with blue laser lines are preferably used for profile measurements on red-hot glowing metals, as well as transparent and organic surfaces. While allowing significantly higher stability, the blue-violet laser beam does not penetrate the measuring object.

These high-performing sensors come in a compact size and offer High profile resolution for the detection of the finest details. The range with its high-profile rate solves various measurement tasks of the profile, width, height, depth, edge, bead, gap, angle, roundness, etc.

Its intelligent features simplify the alignment by adjusting tilted profiles and are ideally suited to dynamic measurement tasks, e.g. in the production control or for robot mounting processes or CAD comparison of the printed component.

(1).jpg)

-160x160-state_article-rel-cat.png)

-205x205.jpg)