With the increase in industrial demands over high quality and higher production rates, automation has been adapted by various industries. Integrating automation reduce production time and cost while subsequently also reduced man-made errors. For example, the errors can be caused by equipment mishandling or manage operations that requiring high precision and concentration.

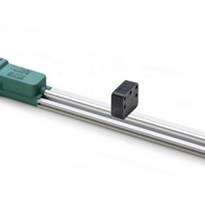

Laser displacement sensors have been increasingly used to drive these effort in industrial automation. Laser displacement sensors works by the laser triangulation principle and detect the change of position based on the position of the light reflected to the detector. This non-contact technology enables a precise and reliable measurement of many types of objects. Advancement in laser sensing technology have also resulted in development of multiple laser technology to enable reliable measurement on challenging applications such as organic materials, shiny and reflective objects as well as fast moving objects. Therefore, the selection of a proper laser displacement sensor for a particular application depends on the required measurement range, target material and complexity of measuring conditions.

Positioning Spreaders on Giant Gantry Cranes

While moving heavy objects such as shipping containers or engines from cars using a gantry crane, chances of accidental collisions or damages are high. Such accidents do not only end up being costly but are also dangerous for the operator to manage them manually. Hence, the components are needed to be placed in the exact position to prevent such operational hazards. Laser long-range sensors are ideal for such scenarios by inculcating millimeter precision positioning and making modern warehousing easier and convenient. They are used for the exact positioning of the spreader for automatically picking up a shipping container. The sensors are attached to the trolley and measure onto the hoist. The spreader can be positioned to the required height with ease or a transverse movement can be initiated during the lifting process.

Positioning of Car Components

The automotive production plants rely heavily on robots to complete tasks that require high accuracy and repetition for putting components in place while manufacturing a motor vehicle. One such case is when the car body is joined to the engine, depending on the automotive manufacturer, laser triangulation sensors can be used to ensure the car body is at the correct position and height away from the engine as they are joined together. The robot delicately handles the car body and rotates it into position and then the sensors mounted on a frame connected to the engine help in getting it into the correct position.

During the installation of car windows, we can use a laser profile scanner to get precise information of all axes. To begin with this, an adhesive bead is required to be applied to the car body where the window is to be glued in place. To get the bead in the right place, a laser profile scanner scans the area ensuring everything is positioned and applied correctly. Then robot is used to manipulate and rotate the window into a position just above where the adhesive bead has been applied. Once this is done, the placement of the window is then checked automatically and thereafter the window is installed.

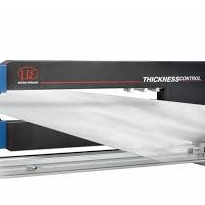

Web-edge Detection in the Calendar of a Paper Machine

The calendar is a set of high-pressure rollers that is used to finish and smoothen paper, textiles and plastics during their production. If the web-edge of the paper is not exactly inline, then the roller’s coating may get damaged when one roller of the calendar presses against the other roller’s coating. Replacing the coating on the roller or replacing the roller itself is very expensive. This is why it is important to control the web-edge of the paper to prevent such errors. In order to prevent such occurrence, two laser profile scanners can be used, one on each side, to determine the exact position of the web-edge of the paper. Having two scanner helps in determining the width of the paper and this information can be sent directly to the next stage in the process. The paper can then be trimmed using information from the scanners about the correct width.

Positioning of Wooden Boards for Sawing

In an automatic sawmill where timber comes in as logs and comes out as fine quality timber products such as planks or boards, laser triangulation sensors are commonly used to control the position of the timber through a variety of stages. As the timber is moved down the conveyor to be sawn, height and width information of the timber is automatically sent to the controller via laser triangulation sensors. Adjustments can then be taken then the saw cuts the timber to size.

Serial Numbers on Car Bodyshells

In a world where there is a high turnover of stolen automotive parts, manufacturers are now using advanced techniques to crack down on this trade. Now, car body identification numbers are punched into the body for added security. Laser triangulation sensors are used to check the machine is at the right height and after the process is completed, they are used to ensure that the correct depth of embossment was achieved.

PCB Boards

Electronics companies from all over the world use PCB boards to mount electronic components to form electronic and electrical circuits. To ensure that high quality is achieved in automated factories as the boards fly down the conveyer, laser triangulation sensors are mounted above the conveyor. These sensors measure whether any excessive or incorrect soldering is done that may cause the board to become bowed or not straight edgeways or if any components are missing on the board. Operations such as this can occur at high speed and are much more accurate and repeatable with a sensor than having a human operator perform the same tasks.

Quality Control of Stamps and Dies in Medicines

As per ISO 18084:2011, stamps and dies used in the manufacture of tablets are under the scrutiny of continuous quality control. In the past, these measurement have been difficult to perform due to the unavailability of appropriate technology. However, today, the measurement and accurate positioning can be undertaken using a confocal chromatic displacement sensor and an optical micrometer to perform the required tasks to ensure that the quality standard is maintained.

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)

-720x400.jpg)

-160x160-state_article-rel-cat.jpg)

-205x205.jpg)