In a collaborative effort with a specialised distributor, Electrodrive successfully addressed the challenges faced by a commercial bakery in moving heavy machinery and equipment within a corrosive production environment. The need for a more efficient and safer solution led to the design and development of a custom stainless steel powered tug.

Manual Handling Strain and Downtime Risks

The commercial bakery's routine involved the regular movement of heavy equipment, including a dough mixer and packaging machine, for cleaning purposes. This manual handling process required 2-3 workers, posing a risk of back and shoulder strain. Moreover, the potential for workplace injuries could lead to increased downtime, affecting overall productivity.

Challenges in a Harsh Cleaning Environment:

Their rigorous hygiene practices involve the use of an industrial sanitiser with potent foaming detergent properties. This highly corrosive substance, employed for cleaning, sanitising, and emulsifying grease, oil, and fats, poses a significant threat to equipment longevity. The acid-like nature of the chemical cleaner used on a regular powder-coated tug (rather than a specialised stainless-steel tug) wouldn't withstand the cleaning processes for more than a few minutes.

Solution: Custom Hygienic Stainless Steel Tug

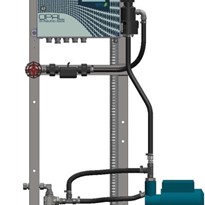

Collaborating closely with a specialised distributor, Electrodrive engineered a tailored solution—the stainless-steel corrosion-resistant Tug Axis 2T. This powered tug was specifically designed to meet the unique demands of the food and beverage industry, providing a hygienic and efficient solution for moving heavy loads.

Benefits of the Stainless Steel Tug:

- Hygienic Design: The stainless-steel body and hitch of the tug are resistant to corrosion, ensuring optimal hygiene in the humid bakery environment. This feature is critical for compliance with industry standards and regulations related to food safety.

- Single-Operator Efficiency: The powered tug allows a single operator to effortlessly move loads of up to 2 tonnes. This not only reduces the manpower required but also mitigates the risk of manual handling injuries, contributing to a safer workplace.

- Ergonomic Visibility: The tug's ergonomic design prioritises maximum forward visibility for the operator, reducing the likelihood of collisions with walls, doorways, equipment, or staff. This feature enhances overall safety within the bakery facility.

Results: Improved Workplace Safety and Efficiency

With the implementation of Electrodrive's stainless steel tug, the bakery has experienced a significant improvement in workplace safety. The streamlined process now requires only a single operator to manoeuvre heavy manufacturing equipment for cleaning, eliminating the need for multiple personnel and reducing the risk of manual handling injuries.

Looking for a Similar Solution?

If you're facing challenges similar to those encountered by the commercial bakery or seeking more information about custom solutions, we invite you to contact our product experts. Electrodrive remains committed to providing innovative and tailored solutions to enhance efficiency and safety in various industrial settings.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)