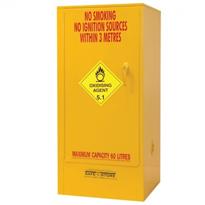

The safety and environmental requirements for storage of chemicals in the factory or mine site are rigorous and if hazardous goods are not stored correctly then there is a risk that there could be a spill damaging the environment or worse still, workers could be injured. Penalties for incorrect storage can be severe so it is important to make sure all chemical tanks and other chemical storage is undertaken according the correct standards.

To safely store chemicals, and other hazardous substances, the correct tanks must be selected, they must be installed correctly, maintained regularly and staff must be aware of any procedures associated with the safe storage of hazardous goods.

The selection of the correct storage tank is dependent on the chemical to be stored, the concentration of the chemical or hazardous good, the temperature that the chemical will be stored at and the method of filling and emptying the chemical storage tank. To find out the chemical compatibility of a tank material, tank manufacturers will be able to provide a chemical compatibility chart. Click here for detailed information.

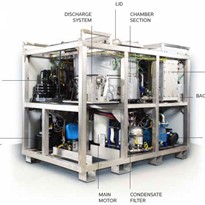

The installation of a tank for chemical storage is critical and there are a large number of standards that must be met. The types of issues that must be dealt with include the level of bunding required, the types of fittings to be used and the level of venting that may need to be installed. For example a simple holding tank for low concentrations of a particular chemical will require no venting however the storage of a volatile chemical may require extensive venting. The design of this type of chemicals storage will require design work to be undertaken by a qualified engineer.

The fittings added to the storage tank should ensure easy and safe filling of the tanks and the efficient and sound way for extracting the chemical from the tank. There will be requirements in some cases for venting as well as agitation. These fittings must all meet the needs of the chemical stored.

The fittings used on a storage tank are critical and are often the weak point of any chemical storage tank. Often if the fittings are not reviewed in detail, the wrong material can be used. An example of this would be where there is a plastic tank installed that then has a galvanised fitting used which could be corroded rapidly by the chemical stored.

Once the chemical storage tank has been installed and is in use the system must be maintained to ensure the fittings do no leak, the tank is maintaining its integrity and that if the tank is outside the bunding is sufficient to handle any rainfall. Chemicals can be corrosive to the tank material and in some cases it is recommended that tanks be replaced every 5 years or at least assessed to ensure the tank has not deteriorated.

The storage of chemicals also requires the staff that is operating plant and equipment on and around the storage tank to have access to and follow the standard operating procedures. Chemical spills are often the result of someone not following the standard operating procedure.

Chemicals storage can be safe and efficient providing the right storage tank is selected, the tank is installed correctly and maintained and the operators follow the standard operating procedures.