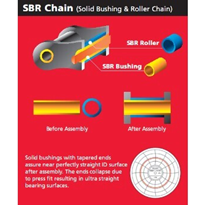

Industrial chain drives under a lot of stress. Transmission roller chains have to handle heavy loads, increasing speeds as you seek to ramp up production, high temperatures, volatile materials and other demanding environmental conditions.

And sometimes, the simple fact is, they can’t handle those things.

Your chain drives let you down. They require more of your time to lubricate and maintain, and they may fail only a few months into their lifetime, requiring expensive replacement. Downtime costs you in lost productivity and earnings, and that’s the last thing that you and your business needs.

Yet you continue, because “that’s how we’ve always done it.”

That doesn’t cut it anymore, especially when there’s a better option available.

A BETTER ALTERNATIVE

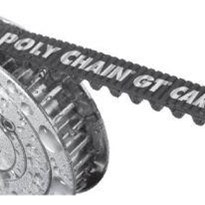

Building on decades of experience in creating optimum solutions for belt drives in both automotive and industrial applications, Gates PolyChain® GT™ Carbon™ belts are well equipped to handle the demands of any manufacturing environment. PolyChain® GT™ Carbon™ is Gates’ most powerful synchronous belt and is specifically designed for optimum performance on high torque, low-speed drives often seen in industrial applications.

An excellent alternative to chain drives, Poly Chain® belts offer many benefits to your business.

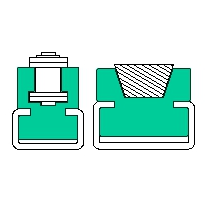

The benefits of Poly Chain® begin with the belt’s innovative, state-of-the-art construction. The body and teeth of Poly Chain® GT™ Carbon™ are constructed of a lightweight polyurethane compound that is specially blended to adhere to the cords and fabric. Carbon fibre tensile cords provide extraordinary power carrying capacity as well as exceptional flex fatigue life. Combined, these factors mean Poly Chain® GT™ Carbon™ has the strength to withstand shocks and surge loading and is virtually immune to abrasions. Being much lighter than steel chain, Poly Chain® GT™ Carbon™ also reduces overhung loads.

Additionally, Poly Chain® GT™ Carbon™ has power ratings up to 30% higher than previous incarnations of Poly Chain® - and yet, it has a multi-year service life, up to three times longer than chains. Similarly, pulley life for Poly Chain® is up to ten times longer than roller chain sprockets.

Think about the time you have to spend on maintaining your chains – lubricating, re-tensioning, removing links. Now imagine how much more efficiently your business would run if you didn’t have to dedicate valuable production time to these tasks. Poly Chain® GT™ Carbon™ belts are completely maintenance free. They do not require messy lubrication or oil baths (a hazard for any food handling environment), or re-tensioning every few months. They will not stretch during service. That means less downtime spent maintaining your drives, and more uptime getting on with the job. It offers 400% greater capacity than HTD belts, 5% energy savings over V-belts, and 99% efficiency for the life of the drive.

Poly Chain® GT™ Carbon™ is inert to most acids, chemicals and water, making it an ideal solution for wet environments – unlike roller chains, which can rust, potentially contaminating food-handling spaces.

Poly Chain® GT™ Carbon™ belts operate on Poly Chain® GT™ pulleys and do not require any adaptation of existing GT2 applications.

SPECIFICATIONS

Poly Chain® GT™ Carbon™ comes in a range of pitches; this range now includes both short and extended custom lengths, to suit a variety of manufacturing purposes.

Short length versions of the belt in 5M and 8M are suitable for industrial markets requiring a short centre distance but high-density power and offer all the benefits listed above.

Poly Chain® GT™ Carbon™ is now available in 19M to handle longer drive centre distances than ever before, while still delivering the same high-power capability, long life and freedom from maintenance that you’ve come to expect. Poly Chain® GT™ Carbon™ offers a massive 96% weight saving versus traditional, comparable transmission roller chains.

The new Poly Chain® GT™ Carbon™ 19M pitch belt can replace even bigger roller chains, open gears and wide multi V-belt drives. Extended length manufacturing capability allows for custom belt lengths with any tooth count (within minimum and maximum length range), a product that is truly tailored to your needs.

All Poly Chain® GT™ Carbon™ belts are fully operational in temperature extremes of -54°C to +85°C and can be used for applications in general manufacturing, food and beverage, timber, agriculture, oil and gas, cement and more.

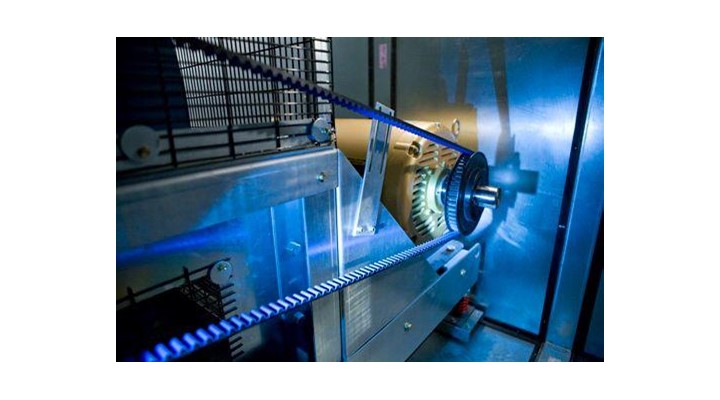

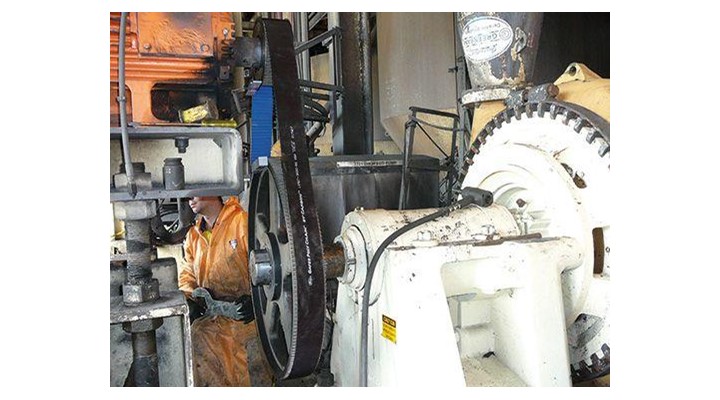

Poly Chain® GT™ Carbon™ is ideally suited to a range of different environments, from food production to fans and pumps. Already, plants around Australia have converted their tired and dirty roller chains to the efficient Gates alternative and are seeing the benefits.

Poly Chain® GT™ Carbon™ is an excellent problem solver. It offers reduced width drive conversions for existing roller chain applications, and over 120,000 possible ratio combinations, making it easy to switch your drives.

STAY AHEAD OF THE CURVE

In today’s fast-paced manufacturing environment, it is critical for your business to stay ahead of the curve. By converting your tired, old roller chain drives to highly efficient Gates Poly Chain® GT™ Carbon™ belts, you’ll be setting your business up for future operating success. Space-saving, weight-saving, time-saving and money-saving, Poly Chain® GT™ Carbon™ drives offer a long and reliable service life.

For more information CLICK HERE.