GKS Packaging prides itself on being able to solve real-world challenges in simple ways. To do this, the company delivers reliable, cost-effective, flexible modular packaging machines, made to meet a company’s requirements.

The company subscribes to the concept of ‘why make things more complicated than they need to be?’.

GKS is a family firm that was founded in a garage by father and son duo, Eli and Ivo Geukes, in 2000. The sale of three machines in their first year helped the team finance a drilling and milling machine and a lathe and welding machine.

In its second year, the company moved to the Ekkersrijt industrial estate and today GKS has developed a wide range of Vertical Form Fill Seals (VFFS), built on the ethos of innovating simplicity

GKS Packaging throws out the rule book on vertical form, fill and seal machines with its innovative design.

When the first vertical form, fill and seal machine GKS Leaf was specifically developed to produce paper bags out of 100 per cent recyclable and compostable paper mono material, it was time to learn more.

VFFS machine innovation and flexibility is all about the ability to not only meet current needs, but adapting to future requirements and trends too, especially when it comes to the consumer needs and wants.

The ability to have a range of VFFS machines that offer the flexibility, innovation and sustainability at mind is critical for manufacturing.

Based in the Netherlands, inventive simplicity, user experience and hygiene are what characterises GKS products.

With its flexible packaging solutions available for all businesses, be it a small family-run business right through to large industrial pack houses, its range of VFFS machines embrace adaptability.

GKS LEAF

GKS LEAF has been designed to do what it needs to do – produce perfect bags with paper, without compromise.

The team at GKS had the mindset that “plastic never existed”. It developed, not just modified, a machine that it said achieved maximum performance of all functions resulting in a perfect seal under high pressure, optimum folding of the bag, perfect shaping, and stable paper transport.

The packaging machine itself is also made from recycled and recyclable materials and the first VFFS (vertical form fill seal) machine with iPad interfaces on both sides of the machine, offering easy access and worldwide availability at low costs.

Fresh produce products, such as potatoes, can be packed in both pillow and stand-up block bottom bags that do not absorb the moisture of the packed products.

The paper retains its strength and structural integrity. Alternatively, the machine operates with conventional packaging film.

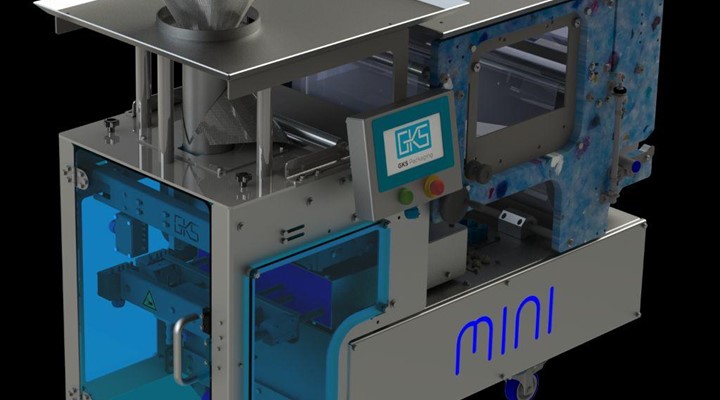

The MINI

The MINI is suitable for medium- to high-capacity packaging applications using relatively small bag sizes.

It is also ideal for processes in which a compact form factor is essential, such as hand sorting and packaging samples or composite products such as nuts and bolts.

The EP 250

The EP 250 is as versatile as it is compact, suitable for retailers who regularly need to package a variety of small series.

It is a stripped down, compact machine that offers the basic options needed for lower volumes, with no unnecessary extras.

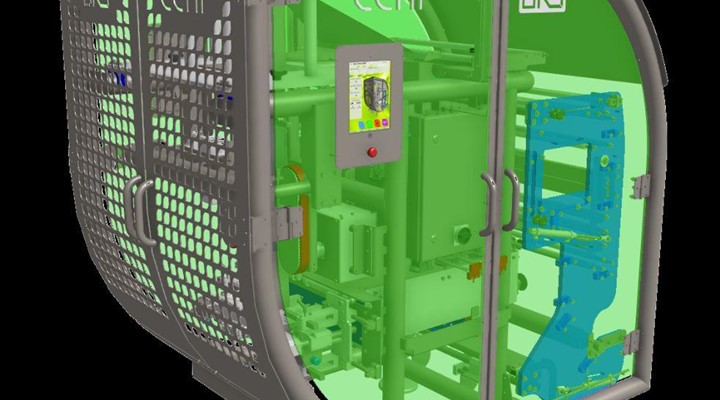

CP Series

The CP Series is based on the new GKS machine platform, which offers modular construction, open structures, ergonomic design, minimal downtime, and low maintenance costs.

The fully stainless-steel machines are partly servo-driven, and feature components from well-known suppliers. Modules can be swapped out in minutes.

UP Series – high volumes without hassle

The UP series handles a range of packaging sizes and volumes. It does what it needs to, without complexity and at a low cost.

Its modular design means individual function groups can be swapped out quickly with minimal downtime, allowing machines, or complete packaging lines, to perform many different functions.

FLOW series

The FLOW series combines unique hygienic design with fully stainless-steel construction without aluminium parts, high packaging speeds and user-friendly control.

The FLOW is designed for medium- to high-capacity packing requirements.

The UP650

The UP650 is a self-contained vertical, form, fill and seal machine that distinguishes itself from other bulk packaging machines through its fundamentally smaller dimensions.

The self-supportive system is suitable for production processes in which bulk volume bags are created without compromising on flexibility.

The NP350

The stainless-steel NP 350 features a user-friendly interface and has been designed for net-packaging with a handle. It features a touch screen for simple operation and control and can be washed down on the outside and inside of the frame.

BRIC bag machine

The BRIC bag machine is designed to create brick-shaped bags. It has a hygienic open design with plug-and-play exchangeable function modules. It also fits on the most VFFS-machines

The range of GKS VFFS machines are supported and available in Australia.

“GKS packaging has a mindset of producing machines that achieve maximum performance that result in perfect high-pressure seals with its a range of VFFS machines that suit all business sizes,” said James White, sales and marketing director at Select Equip.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)