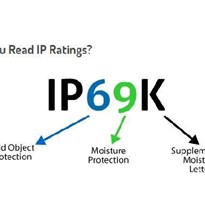

LMK THERMOSAFE [UK] is proud to announce that all their Industrial Heating Jackets featuring reliable capillary thermostats are now rated at IP54 Ingress Protection.

This improvement compliments its jackets with industrial quality digital thermostats and its unparalleled Hazardous Area “Inteliheat” range which are also IP54 ingress protected.

For weather exposed outdoor applications, the fixed thermostat “Weatherheat” jackets are IP56 ingress protected.

LMK Thermosafe are the only Industrial Heater Jacket to have this level of protection.

Known internationally for their quality and efficiency, LMK Thermosafe Industrial Heating jackets now have an extra level of protection for all working environments.

SBH Solutions are the Australasian distributor for LMK Thermosafe Industrial Heating equipment.

Please do not hesitate to contact us for your Industrial Heating Requirements.

(1)-205x205.jpg)

-205x205.jpg)