A focused approach to action

On March 27, 2019, the City of Hamilton joined another 490 Canadian municipalities, declaring a climate change emergency that threatens cities, regions, provinces, nations and the world at large. In doing so, the city has joined forces with an international movement to take action now. As a part of the declaration, Hamilton Water committed to aggressively reducing NRW. In addition, as the largest energy user in the city, accounting for about 6% of the annual budget, Hamilton Water is on a mission to reduce energy consumption. Since potable water requires pumping and treatment before it is used, and that pumping and treatment requires energy, reducing NRW will also reduce energy consumption.

In 2019, Hamilton Water conducted a pilot project utilizing new leak detection technology that was expected to significantly improve results. This allowed the city to test new technology and do a basic cost/benefit analysis before fine-tuning and optimizing a permanent proactive leak monitoring program. The pilot area was chosen based on geographical areas of concern, where water leaks do not typically surface, since the water leaks into the subsurface soil and rock. These hidden leaks account for a large amount of NRW and can be far more damaging to the pipe network, with erosion of pipe bedding leading to major pipe breaks and even damage to foundations of roads and buildings. Hamilton Water dedicated a water distribution operator and supervisor to work with Mike Howard, a leak detection expert from MJH2O, for a four-month pilot. Using Gutermann Zonescan 820 correlating radio loggers, a systematic deployment approach called “lift & shift” was initiated to survey selected pipe sections and detect leaks.

How it works

Each day, an area was created in a project file. Loggers, or sensors, were then deployed in the area by magnetically attaching them to main line valves and hydrant secondary valves. Spacing of the loggers averaged every second hydrant, with main line valves included where necessary. This allowed the logger to listen for leak noise 100 metres in each direction. With 38 loggers, the team tested an average of 7.5 km of watermain each night.

The loggers were programmed to turn on between 2:00 a.m. and 4:00 a.m. to record noise levels at each location. Sound signals were recorded and saved for future correlation and leak detection purposes. Loggers were then picked up the next morning and the Zonescan Smart software retrieved the data collected and programmed the loggers for the next selected area. The software tagged each logger to a GPS location on Google Maps, which was then uploaded and saved to Zonescan.net. Information collected was automatically correlated to pinpoint the leak location. A correlation report for each location and findings from all loggers were reported to the water management team daily, so that action could be taken as required.

Achieving better results

Leak detection technology has come a long way, and most of that advancement has happened in recent years. In the past, the city has used geophone technology, and correlators to locate leaks where the rough location of the leak was unknown and the distances were relatively high.

The problem is that heavy road traffic or even water usage can interfere with pinpointing the exact leak location. Digging a dry hole (holes where there are no leaks) costs approximately $5,000. Prior to this new leak detection technology, Hamilton Water was digging 30 – 50 dry holes per year, leading to an annual spend between $150,000 and $250,000. The annual cost of the pilot was $100,000, so, on this metric alone, the proactive leak detection program proved its return on investment.

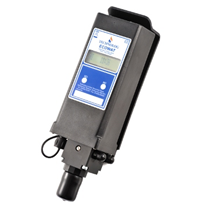

The Gutermann approach uses three methods to cross correlate leak location. First is the Zonescan logger information followed by on-site correlation using Aquascan, and finally sonic leak detection using the Aquascope3 leak detector. This approach increased the accuracy of each leak identified. During the pilot, 180 km of pipes were inspected, with 95 potential water leaks or watermain breaks identified. Staff investigated these locations and confirmed and repaired 67 water leaks or watermain breaks. A further 20 leaks were detected on private residence lines. The overall number of watermain breaks for 2019 was 332, which amounted to repair costs of $2.2 million (including excavation, repair and temporary restoration), and permanent restoration costs of approximately $580,000.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)