Implementing an industrial serial device server can replace the front-end PC, eliminate manual monitoring processes, and provide remote management. A Virtual COM Driver, provided with most serial device servers today, can provide continued use of existing application software found on the shop floor.

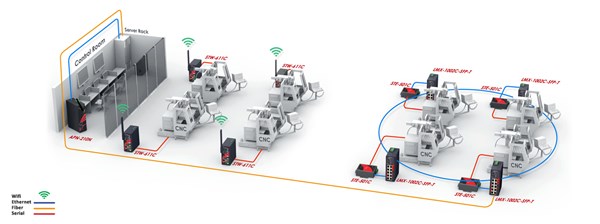

For network infrastructure, there are two types of connectivity solutions: hardwiring or wireless. A hardwired setup can incorporate network redundancy through a ring topology to ensure that connectivity and data will not be lost. A wireless setup can be beneficial if the locations of the machines require relocation regularly.

Challenges

- Factory environment with harsh conditions

- Legacy serial equipment networking capability

- Cable installation time

- Cable distance restrictions

- Reliable data communication

- Long lasting MTBF networking equipment

- Flexible network layout

Application Requirements

- Harsh environment industrial grade networking devices

- Capability to connect legacy serial devices to TCP/IP network

- Seamless and reliable data transmission

- Redundant network with fiber link

- Rapid deployment

- Ease of use network configuration user interface

- Shock & vibration resilience

- High MTBF and wide operating temperature range support

We have a range of industrial network products to help overcome your challenges, call or email today to see how we can help.