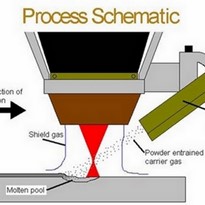

The well-focused laser beam melts the base material and an additive powder to create a wear and corrosion resistance overlay.

Unlike thermal spraying or chrome plating, LaserBond® cladding provides a strong metallurgical bond with the advantages of minimal dilution of the base material, exceptional thickness control, and a small heat effected zone.

The automated laser cladding system ensures the process can be precisely repeated, resulting in a high quality homogeneous coating deposition critical in high demanding environments. As clad material can be varied, critical magnetic and non-magnetic components can be protected with optimal coatings. Standard LaserBond® overlay options include Tungsten Carbide, Stainless Steels, Nickel alloys such as Inconel, and Cobalt alloys such as Stellite.